Industrial Decolorization: Activated Carbon & Ion Exchange Solutions

In pharmaceutical manufacturing, food and beverage production, cosmetics, and environmental remediation, decolorization is a critical purification step that removes unwanted pigments and colored impurities from liquid products and process streams. Achieving efficient color removal while maintaining product quality and minimizing operational costs defines success in these applications.

What this article covers:

- What is industrial decolorization with activated carbon and ion exchange?

- Which industries use decolorization processes?

- How does Rotating Bed Reactor technology compare to stirred tanks and fixed bed reactors?

- How to eliminate filtration steps and reduce decolorization processing time?

- How to scale decolorization from lab to production?

What is decolorization?

Decolorization is the process of removing colored compounds and impurities from liquids through adsorption. Activated carbon and ion exchange resins are the most common solid-phase materials used for this purpose, capturing ionic and organic colorants through surface interaction and pore entrapment.

Applications across industries

Pharmaceutical and API manufacturing

Remove color impurities from intermediate and final API solutions while preserving product purity and extending adsorbent lifetime. Learn more about production-scale activated carbon decolorization.

Food, beverage, and cosmetics

Decolorize natural oils, botanical extracts, and viscous feedstocks efficiently—including challenging applications like cannabis extracts and specialty ingredients. See how the RBR handles viscous liquid decolorization.

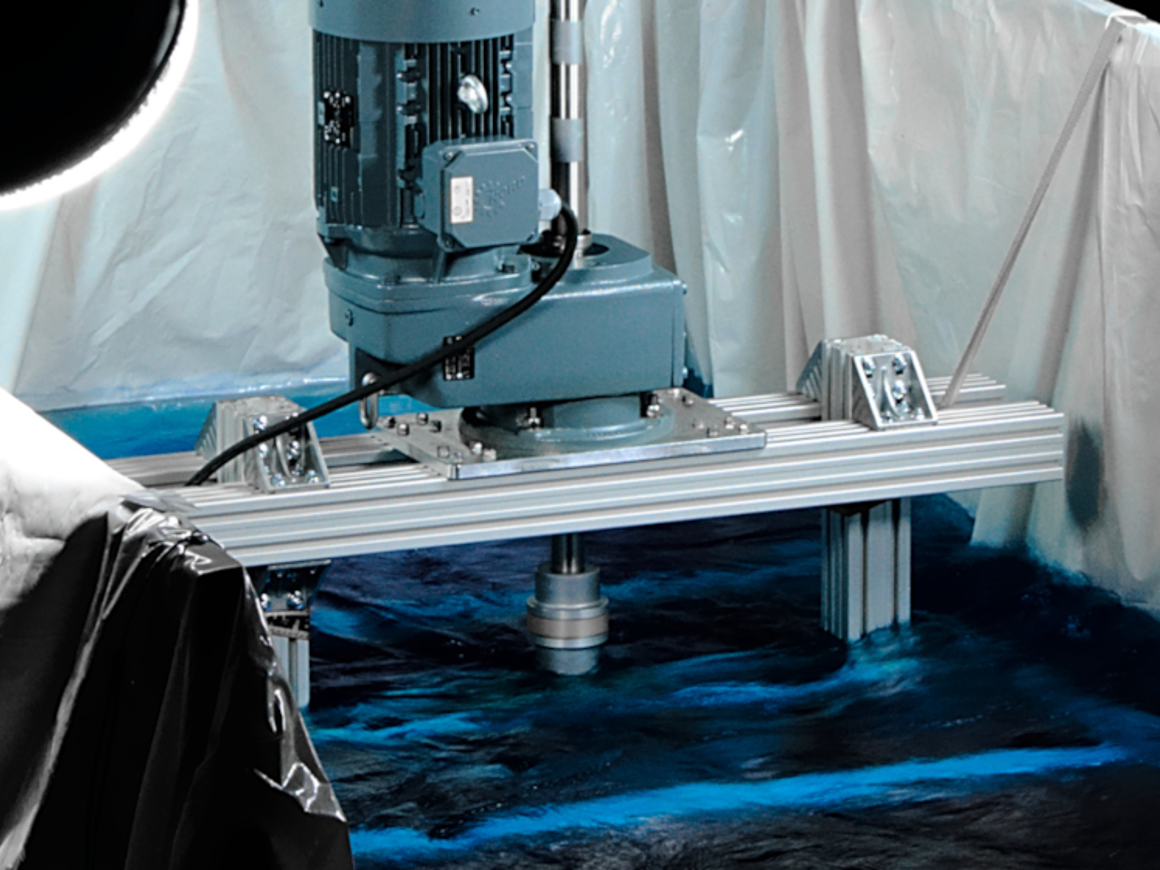

Environmental and water treatment

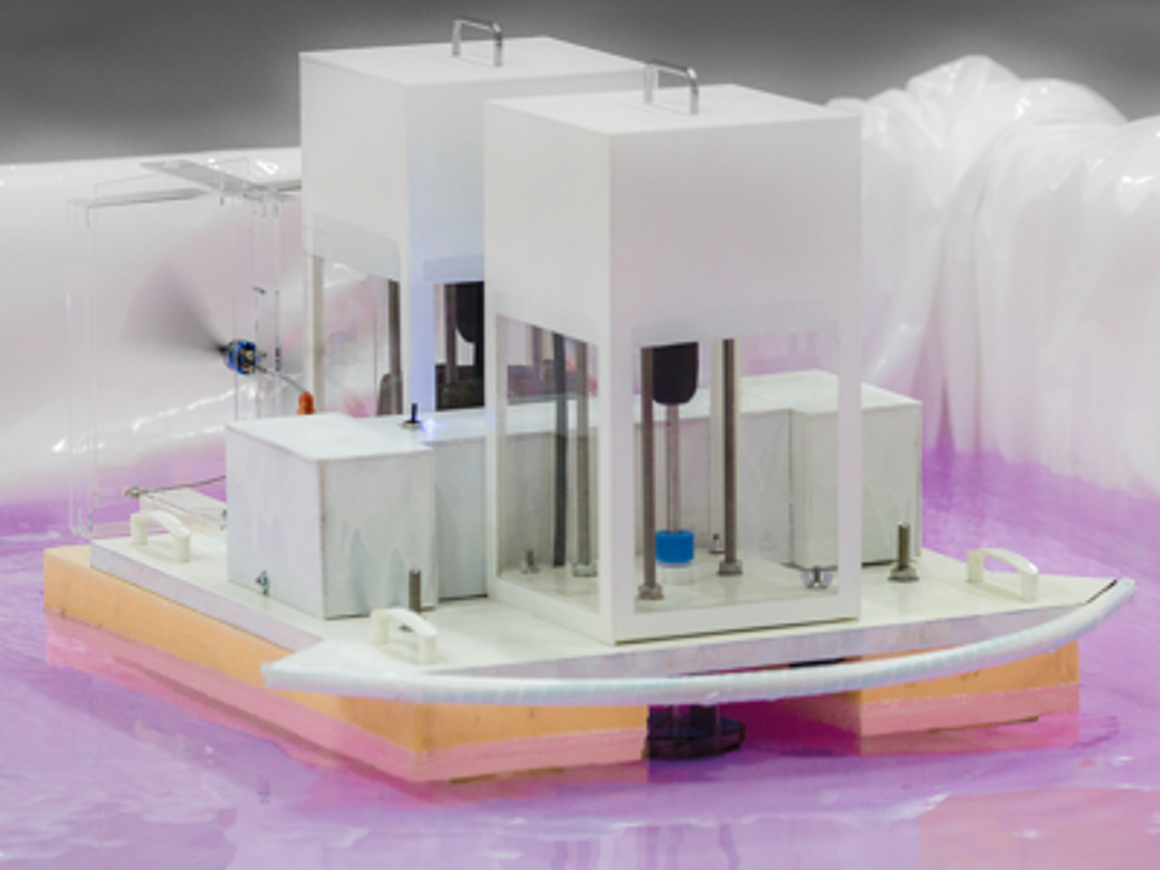

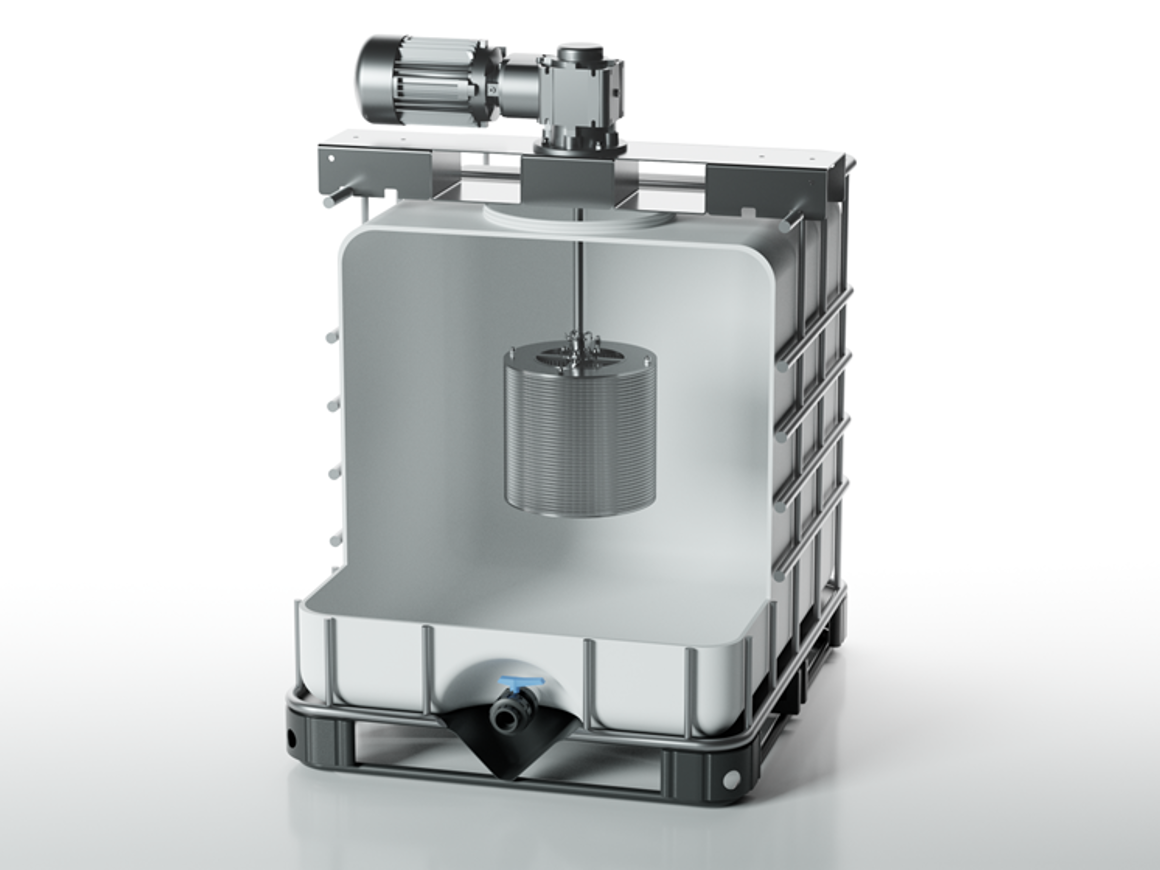

Deploy mobile or in-tank systems for contaminated water treatment, wastewater remediation, and recirculation of out-of-spec production batches. Discover mobile reactor solutions.

Process intensification

Integrate decolorization into continuous or connected systems using compact RBR units that process large volumes with minimal footprint. Explore high-throughput processing systems.

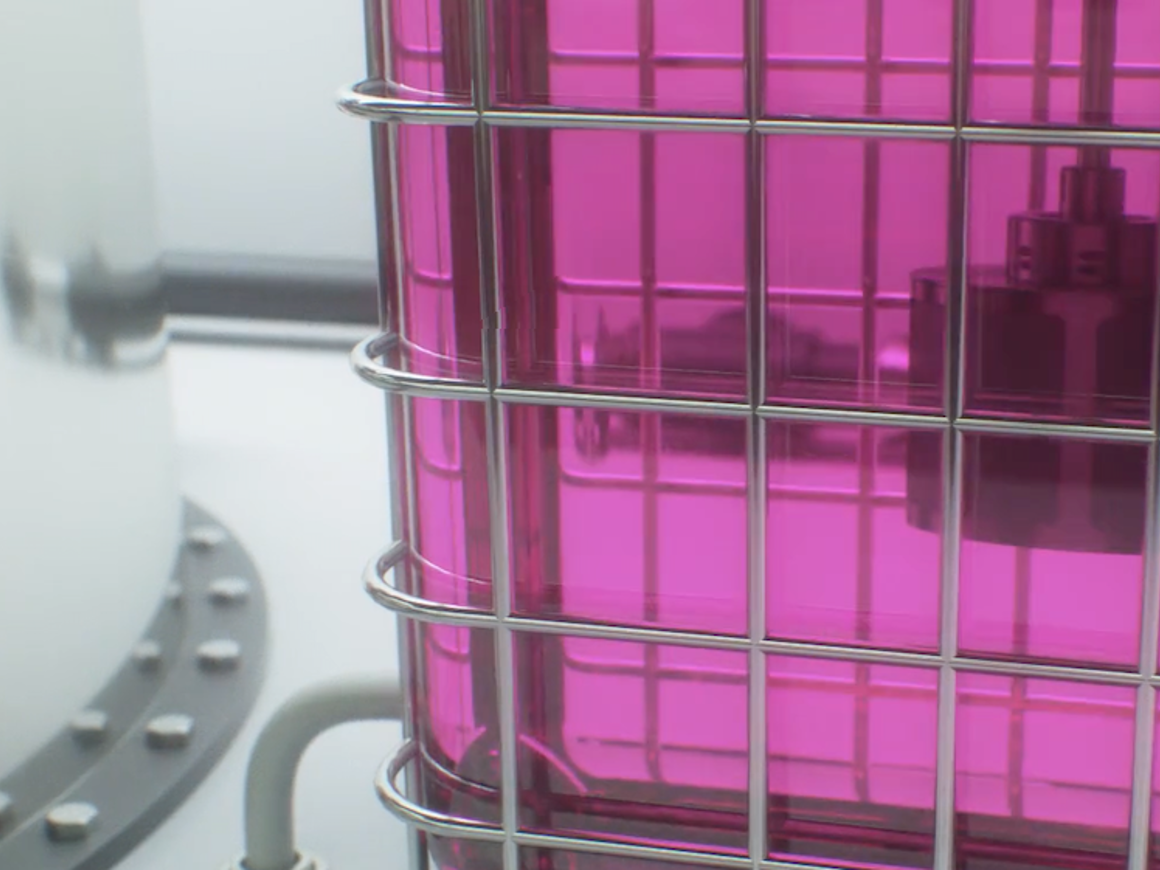

Decolorization with Rotating Bed Reactor technology

Traditional decolorization methods using stirred tanks or fixed bed reactors face significant limitations. Stirred tank reactors cause mechanical damage to adsorbent particles, creating fines that require time-consuming filtration, while fixed bed reactors often limit throughput due to low flow rates. Both approaches extend processing time and increase operational costs.

SpinChem's Rotating Bed Reactor (RBR) technology delivers a faster, cleaner, and more economical alternative. In direct comparisons with fixed bed reactors, the RBR achieves the same decolorization level in 60% less time, or can reduce adsorbent loading by 50% while maintaining the same processing time.

Key advantages of RBR technology for decolorization:

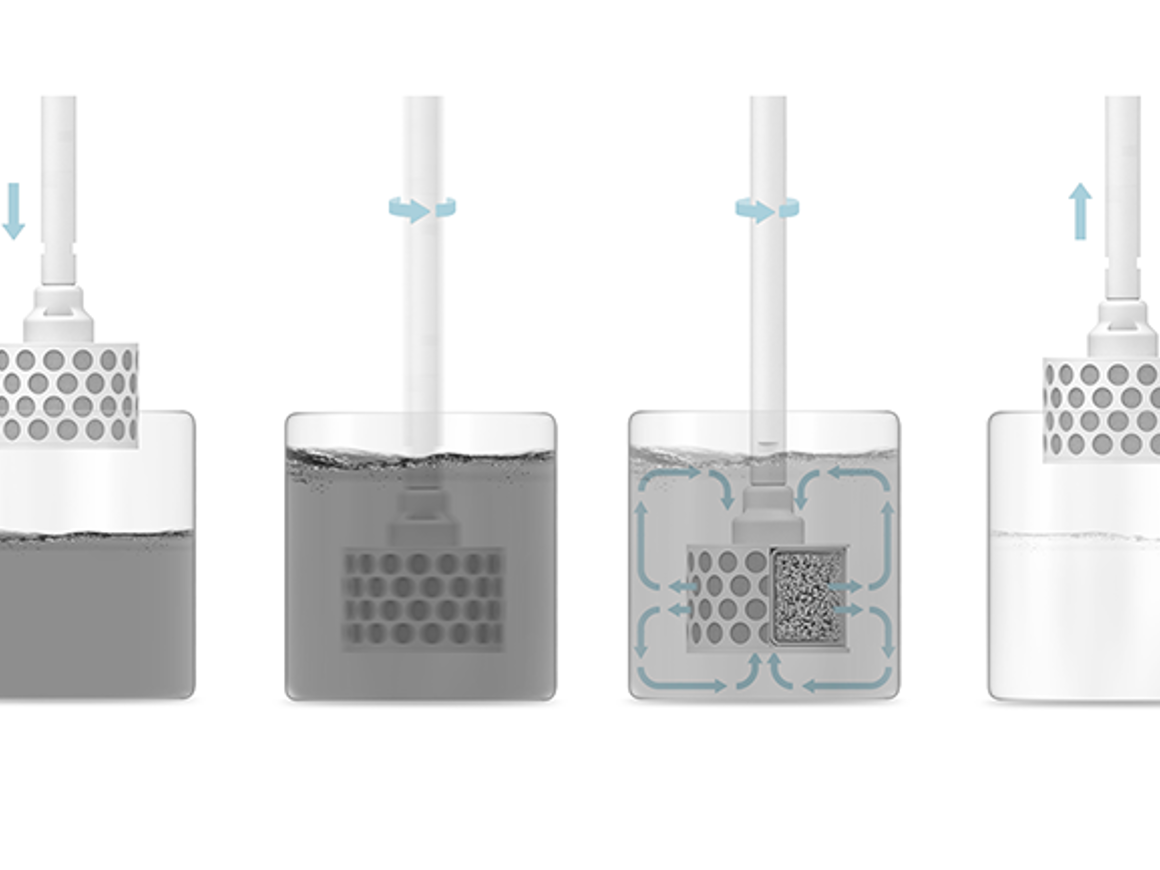

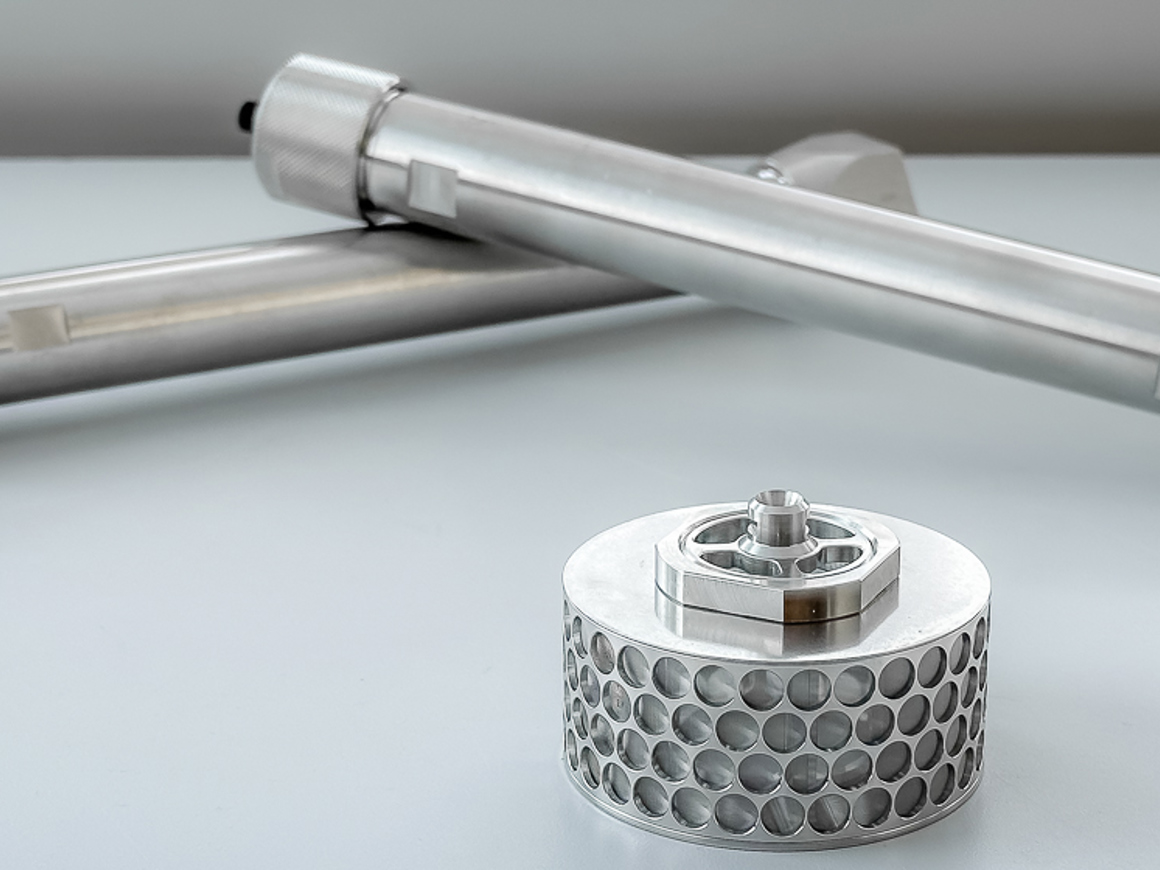

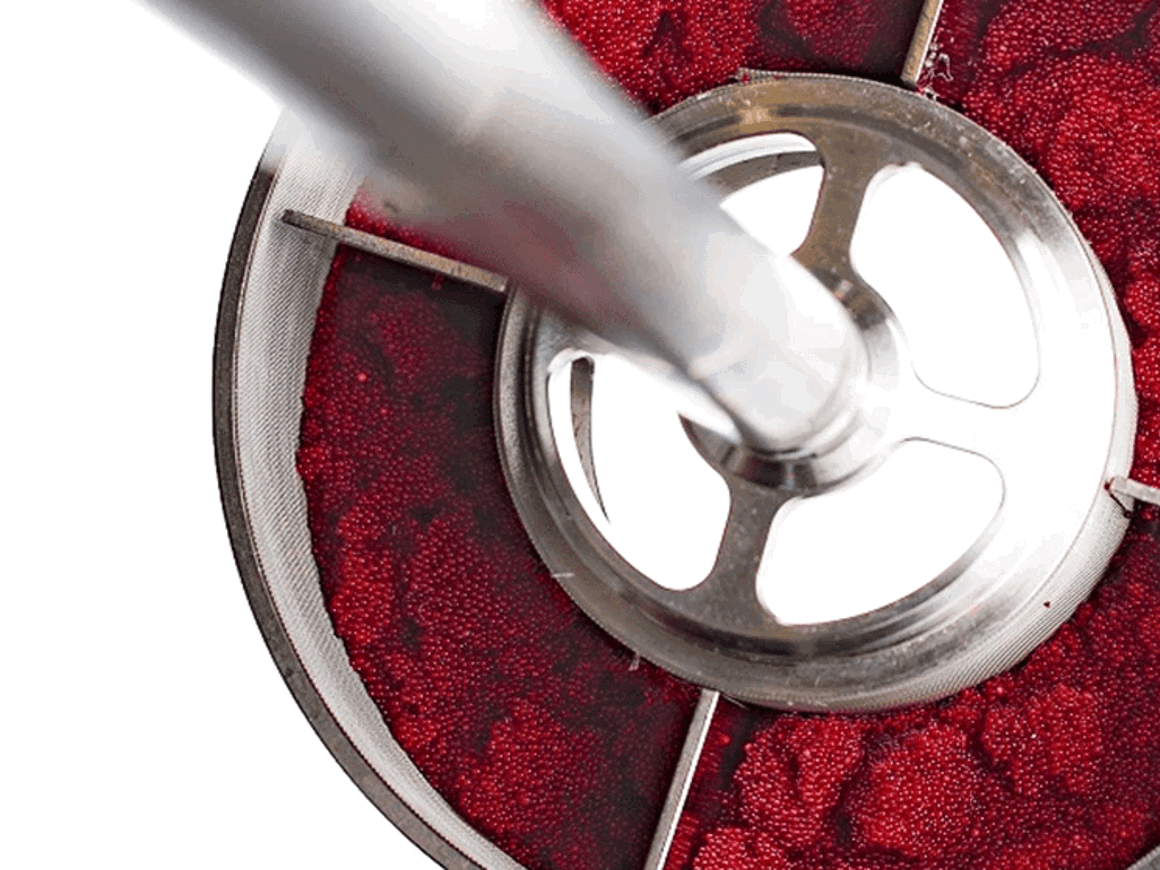

Protected solid phase

The RBR contains activated carbon or ion exchange resin inside a rotating cylinder, eliminating mechanical grinding and the formation of fines that complicate filtration.

Enhanced mass transfer

Rotation generates continuous flow through the packed bed, achieving up to 10x higher removal levels compared to conventional stirred tanks, even for challenging viscous solutions.

Elimination of filtration

With solid phase fully contained and protected, product can be drained directly after treatment. No filtration step required.

Scalable from lab to production

The same technology scales seamlessly from benchtop screening to industrial volumes exceeding 100 m³, with proven performance in mobile systems and large-scale 7,000 L deployments.

Why choose Rotating Bed Reactors for decolorization?

Companies facing regulatory compliance requirements, sustainability mandates, and cost pressure benefit from RBR technology through:

- Faster processing: Up to 60% time reduction compared to batch reactors

- Lower operational costs: Extended adsorbent lifetime and eliminated filtration steps

- Higher product yield: Reduced material loss and simplified downstream processing

- Improved sustainability: Reusable solid phase and reduced waste generation

- Easy integration: Modular systems fit existing infrastructure without major capital investment

Whether you need to meet stringent pharmaceutical purity standards, recover off-spec production batches, or implement cost-effective purification at scale, rotating bed reactor technology delivers measurable improvements in decolorization efficiency.