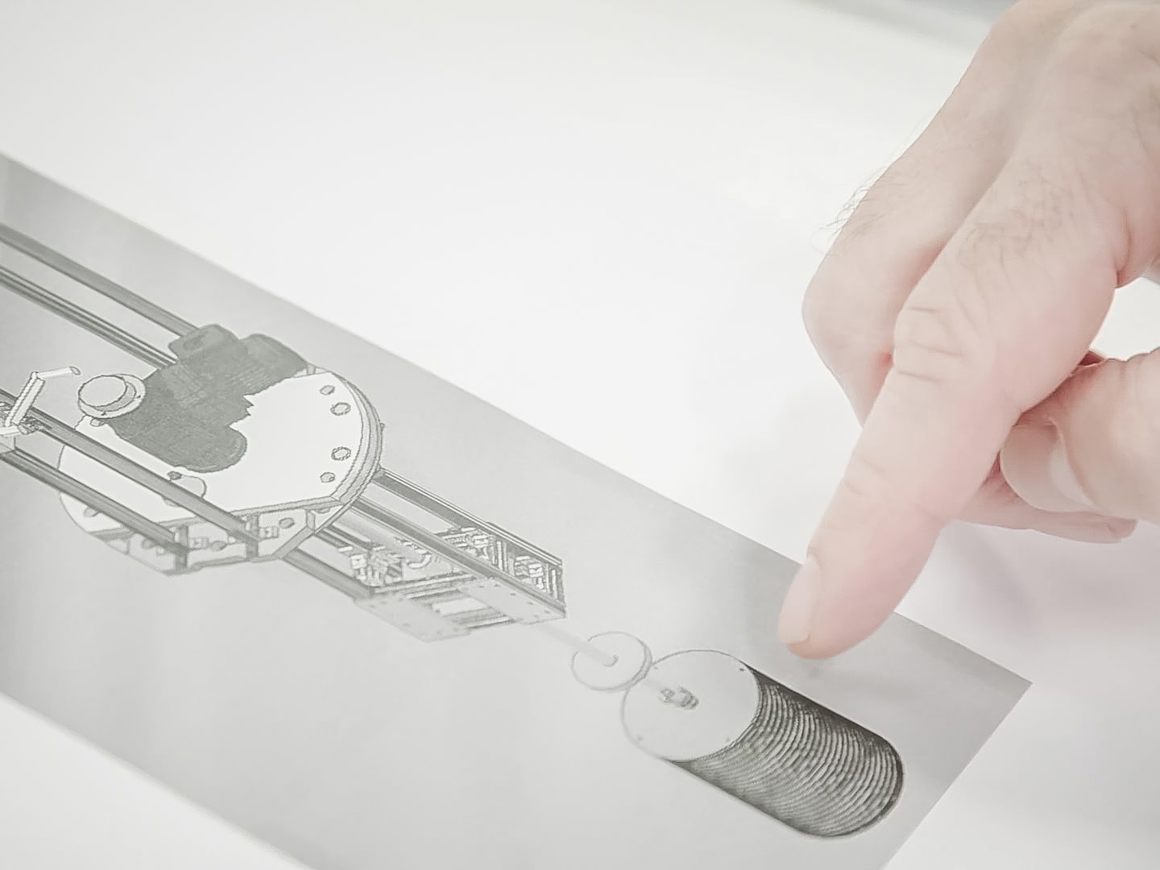

SpinChem® Essentials kit MiniRBR

SKU: #9014-00285 Miniature rotating bed reactor kit containing 1 MiniRBR and 1 tube vessel or fast, reproducible screening of catalysts, enzymes, and other solid phases. Note: Table rack and stirrer kit are not included. Price: €99