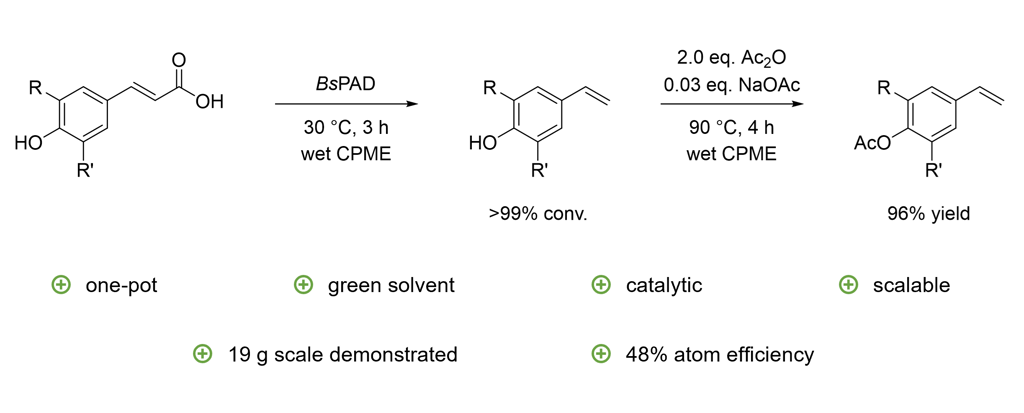

“As renewable lignin building blocks, hydroxystyrenes are particularly appealing as either a replacement or addition to styrene-based polymer chemistry. These monomers are obtained by decarboxylation of phenolic acids and often subjected to chemical modifications of their phenolic hydroxy groups to improve polymerization behaviour. Despite efforts, a simple, scalable, and purely (chemo)catalytic synthesis of acetylated hydroxystyrenes remains elusive. We thus propose a custom-made chemoenzymatic route that utilizes a phenolic acid decarboxylase (PAD). Our process development strategy encompasses a computational solvent assessment informing about solubilities and viable reactor operation modes, experimental solvent screening, cascade engineering, heterogenization of biocatalyst, tailoring of acetylation conditions, and reaction upscale in a rotating bed reactor. By this means, we established a clean one-pot two-step process that uses the renewable solvent CPME, bio-based phenolic acid educts and reusable immobilised PAD. The overall chemoenzymatic reaction cascade was demonstrated on a 1 L scale to yield 18.3 g 4-acetoxy-3-methoxystyrene in 96% isolated yield.”

Highlights:

- “To facilitate easy biocatalyst recovery after the first reaction step, we decided for a rotating bed reactor…”

- “…the solvent was evaporated under reduced pressure to give 18.3 g of the product AMS (96% yield, 99% HPLC purity)…”

- “… a heterogenized biocatalyst allows compartmentalization, recovery, and reuse, all potentially enhancing its practical applicability and productivity.”