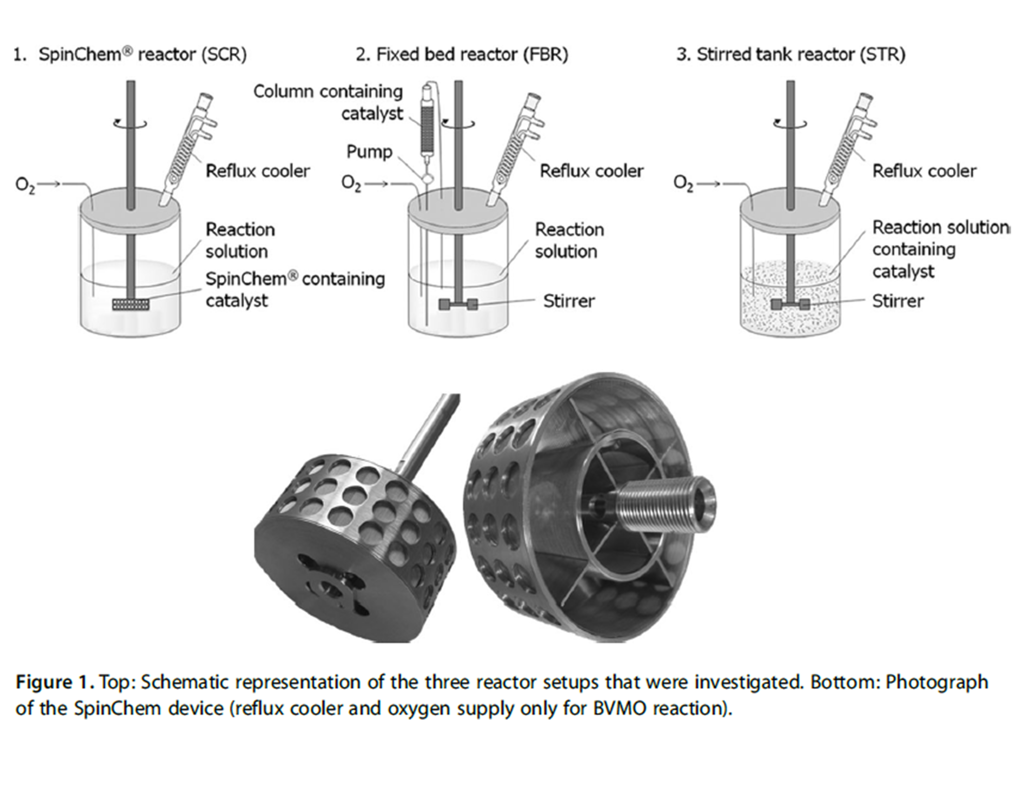

“Biocatalysis has become highly competitive with classical (asymmetric) chemical routes that use transition-metal catalysts, especially in combination with new methods for enzyme discovery and protein engineering, as recently shown for the synthesis of the drug Sitagliptin. The cost-effective application of enzymes, in particular for the synthesis of cheap products, requires immobilization of the biocatalyst (or the encapsulation of whole cells) to enhance their long-term stability and facilitate their reuse. At the same time, immobilization of the biocatalyst should enable the use of established reactor setups, such as fixed-bed reactors (FBRs), instead of simple stirred-tank reactors (STRs, Figure 1). FBRs are used, for instance, for the large-scale production of chiral amines or emollient esters for the cosmetic sector by using lipase catalysts. However, several disadvantages are encountered with FBRs, which depend on, for example, the length, diameter, and particle size in the reactor, the flow rate, the pressure drop within the column, and reactant and pH gradients, as well as inactivation profiles after extended use. In contrast, the more operationally simple STR encounters mechanical challenges for the carrier, which results in abrasion of the biocatalyst material and severe damage of encapsulated whole cells beside the fact that the recycling of the immobilized biocatalyst is rather laborious."

"Herein, we have investigated the use of an alternative setup for the application of immobilized enzymes and encapsulated whole cells. This SpinChem reactor (SCR; SpinChem is a registered trademark by Nordic ChemQuest AB, Umeå, Sweden) enables the simultaneous stirring and efficient percolation of a liquid through packed particle beds, which is implemented by a hollow stirring device that allows the solid reaction chamber to be located inside the stirring element itself. The SCR can be seen as an evolution of the standard basket reactor. The basket reactor, first published by Carberry in 1964, is a setup in which four baskets rotate inside a well for gas/solid reactions. This concept was later developed as the “annular spinning basket reactor” by Mahoney et al. in 1978. However, in the SpinChem reactor, the solid phase (such as an immobilized enzyme) is present in the stirring element itself in up to four separate compartments, which provides greater mixing and flexibility compared to the basket reactors.”

Highlights:

- "[...] the immobilized transaminase was better protected from mechanical forces in the SpinChem device."

- “Next, reuse and downstream processing were studied in the SCR and the STR under identical conditions. In the case of the SCR, this study was simply performed by taking the stirrer out of the reactor and washing it three times in small beakers under stirring for 30 s. Then, the biocatalysts that were present in the SpinChem compartment were ready to use in the next cycle. In the STR, the reaction solution was first filtered, followed by washing the immobilized catalyst before the next cycle was started. These recycling studies revealed that, for the transaminase reaction, the SpinChem system was superior: 93% relative activity was recovered in the SCR compared to only 62% in the STR (Figure 5).”