The rotating bed reactor (RBR) is a tool for treating very large volumes of liquids; valuable batches of product or problematic liquid waste. In the latter case, the contamination is concentrated to a smaller volume of solid waste, often reducing the mass and volume of the waste many thousands of times.

SpinChem will design a treatment system for your individual case and to your requirements. We have the capabilities to build and test complete systems, as well as predict performance using computational models and in-house pilot tests. Legacy waste in the nuclear energy sector, unresolved for many decades, have been cleared for release in weeks after the implementation of a rotating bed reactor.

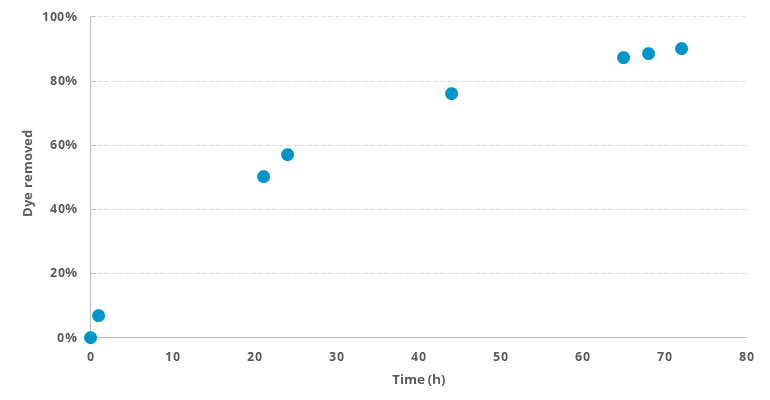

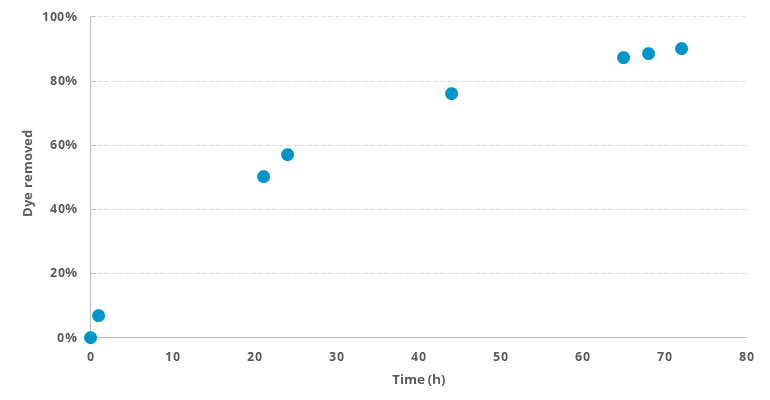

To prove the application of an RBR in very large liquid volumes the benchtop model RBR S2 (which normally operates on 120 mL of liquid) was installed in an IBC containing 780 L of water and 400 mg of methylene blue. The RBR was filled with activated carbon and rotated at 800 RPM. The amount of dye in the solution was measured by spectrophotometry. Roughly 90% of the dye was removed in the first 70 hours. The liquid-to-solid ratio was more than 27,800(!), and still the RBR homogeneously treated the entire volume.

With a larger RBR, and using a larger loading of adsorbent, the decolorization of the IBC is much faster. Still, this experiment showed that even a very small rotating bed reactor can handle volumes 27,800x larger than itself.

The rotating bed reactor technology was deployed in the nuclear energy sector on a tank containing 90 m3 of water, wherein a contaminant was removed by adsorption. The RBR contained only 14 L of adsorbent at a time, and the 90,000 L of liquid waste was reduced to 57 L of solid waste.