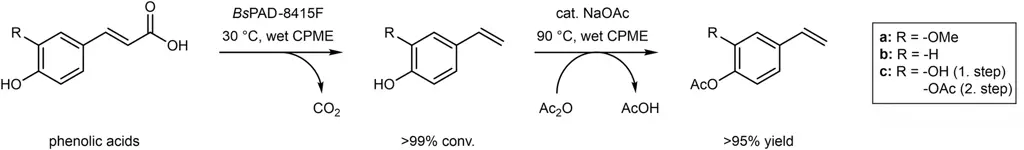

"The valorization of lignin-derived feedstocks by catalytic means enables their defunctionalization and upgrading to valuable products. However, the development of productive, safe, and low-waste processes remains challenging. This paper explores the industrial potential of a chemoenzymatic reaction performing the decarboxylation of bio-based phenolic acids in wet cyclopentyl methyl ether (CPME) by immobilized phenolic acid decarboxylase from Bacillus subtilis, followed by a base-catalyzed acylation. Key-to-success is the continuous control of water activity, which fluctuates along the reaction progress, particularly at high substrate loadings..."

This process happens in two steps, all in one container. First, an enzyme breaks down certain plant-based acids. Then, a chemical reaction adds an acetyl group to the resulting molecules. The enzyme used is called BsPAD, which comes from a type of bacteria (Bacillus subtilis). It's attached to a special resin to make it easier to use. The second step uses a common chemical called sodium acetate. This process can work on different plant-based acids, such as ferulic acid, p-coumaric acid, and caffeic acid, depending on what the enzyme can handle.

Highlights:

- This study investigates a novel approach for intensifying the chemoenzymatic synthesis of bio-based styrene derivatives by controlling water activity in the reaction.

- SpinChem's The rotating bed reactor (RBR) technology enabled high substrate loading reactions with continuous conversion

- Prevented enzyme deactivation during the process

- Demonstrated potential for industrial applications through scalability, robustness, and efficient resource utilization.