The Plug-In Rotating Bed Reactor (RBR) solves these problems by offering a mobile, easy-to-connect solution that integrates with existing vessels or liquid flows. No major modifications are needed, and the installation is quick. With the Plug-in RBR, you gain the flexibility to meet the evolving demands on your process.

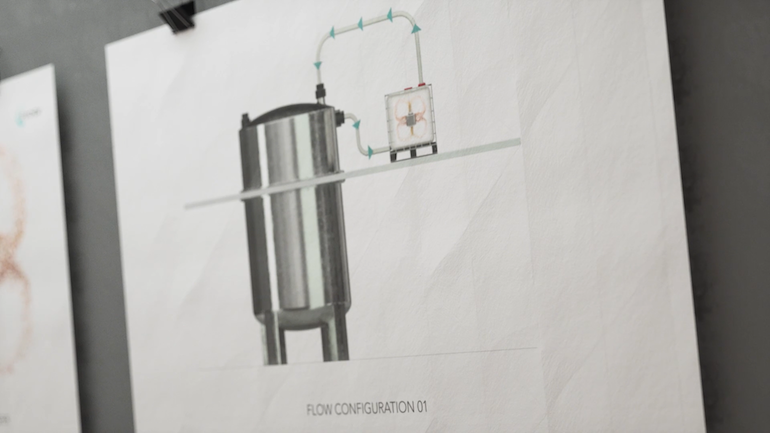

In this application we decolorized a reactor vessel containing 7,500 L of solution, using a small-footprint Plug-in system. The volume of the mobile reactor was only 50 L, and the footprint was that of a single shipping pallet. The plug-in system, housing the RBR S14 containing 12 L of the ion exchange resin Purolite NRW1160, was connected to the main reactor. After recirculating the liquid from the main reactor vessel to the small plug-in system, the ion exchange resin had captured the ionic colorant.

Reach out to SpinChem today to learn how we can fit a technical solution to your process!