Nuclear

AtkinsRéalis and SpinChem have a collaboration agreement to deploy Spinionic® solutions in the nuclear sector. Spinionic® is a registered trademark owned by AtkinsRéalis.

As industries expand to meet the demands of mankind, the reliance on nuclear energy likewise increases considerably to fulfil energy needs. However, the nuclear power industry generates waste that is critical to be taken care of. This waste is classified according to radioactivity as either: low-level, intermediate-level, or high-level. Each effluent has its own characteristics, which determine whether it must be disposed, recycled, or stored on-site. It is important that the nuclear waste is treated to ensure that nuclear power remains a viable choice and a key contributor to the energy mix for future generations.

For the treatment of liquid waste, several well-established technologies exist. One such technology that aims to increase efficiency and to reduce cost is Spinionic™.

Spinionic™

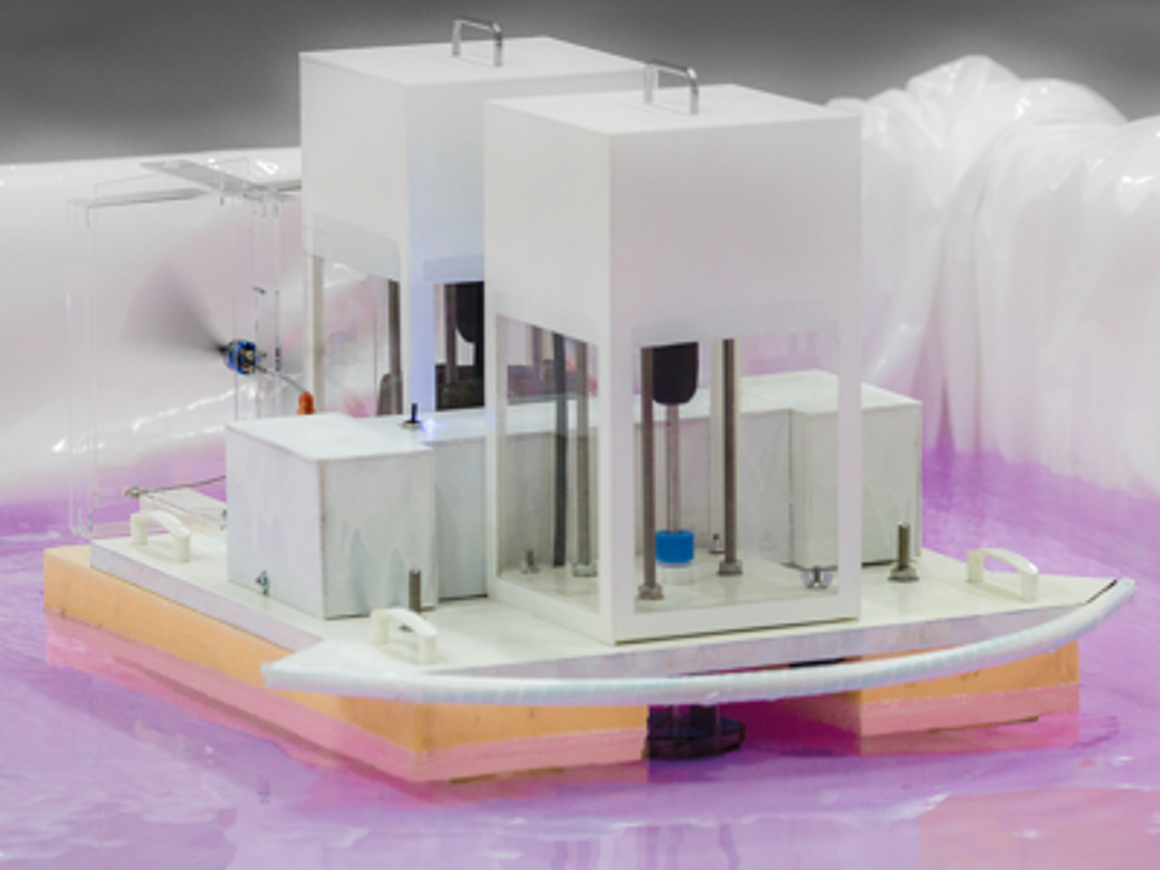

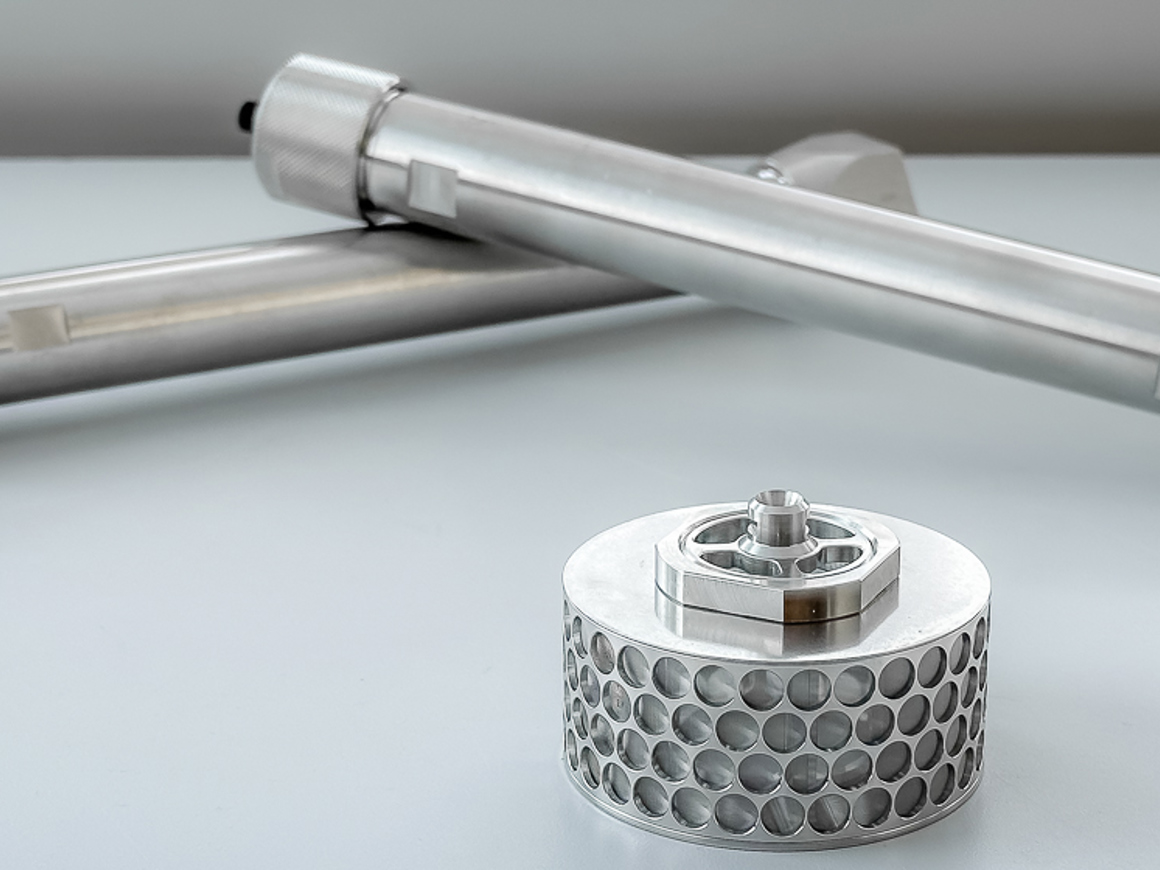

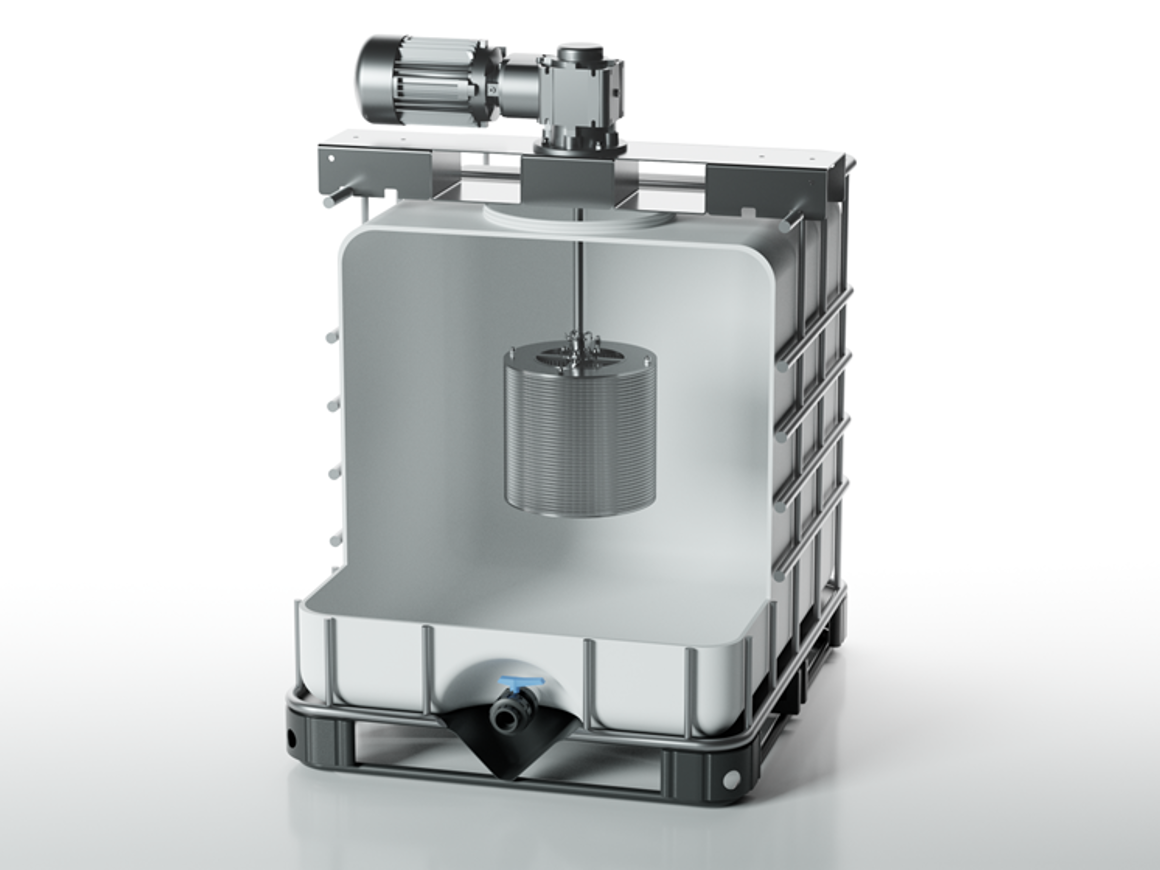

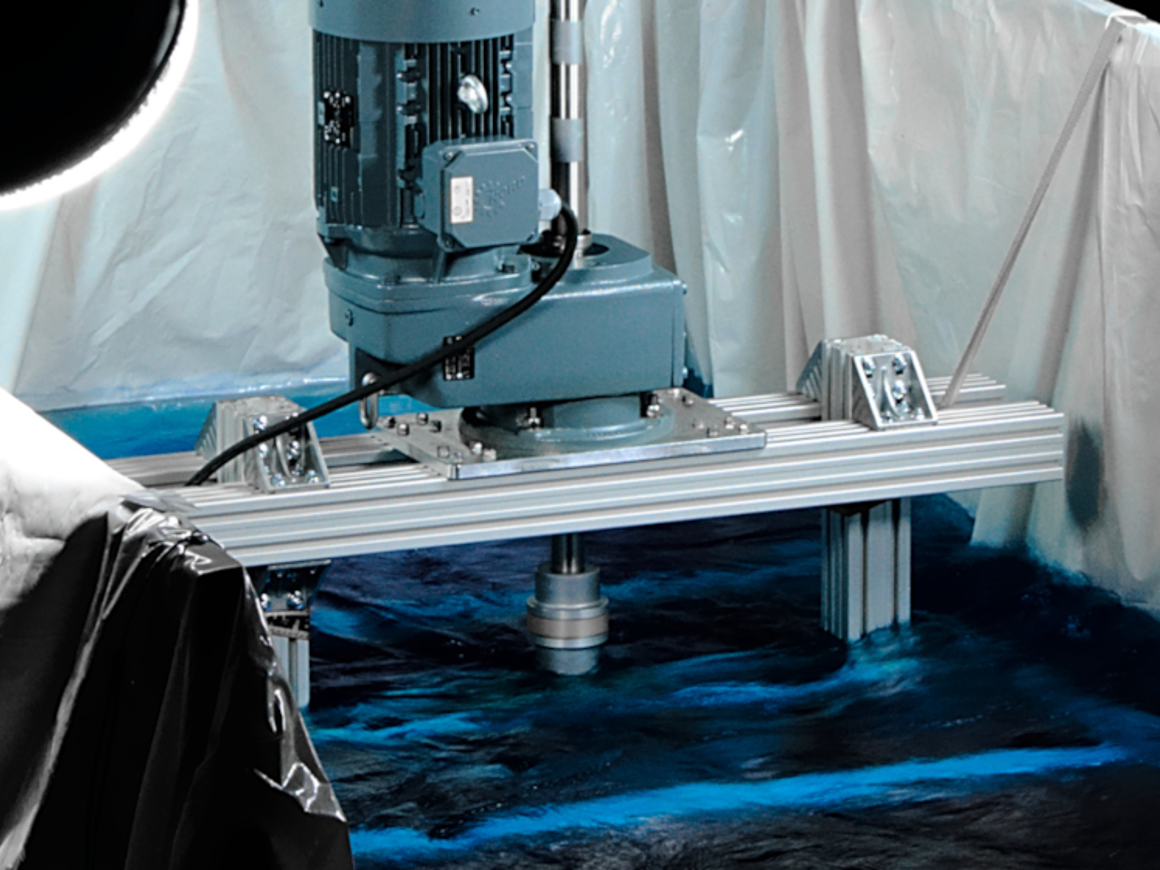

Spinionic™ is a non-nuclear solution to de-contaminate liquids and refers to the tested and patented Rotating Bed Reactor (RBR). Its’ design is flexible and can be used in situ for a range of applications such as to treat tanks of radioactive waste, or to processes continuous waste streams. It can be used as a pre-treatment upstream of installed equipment to remove impurities, and also as a polisher downstream of existing equipment.

Technology

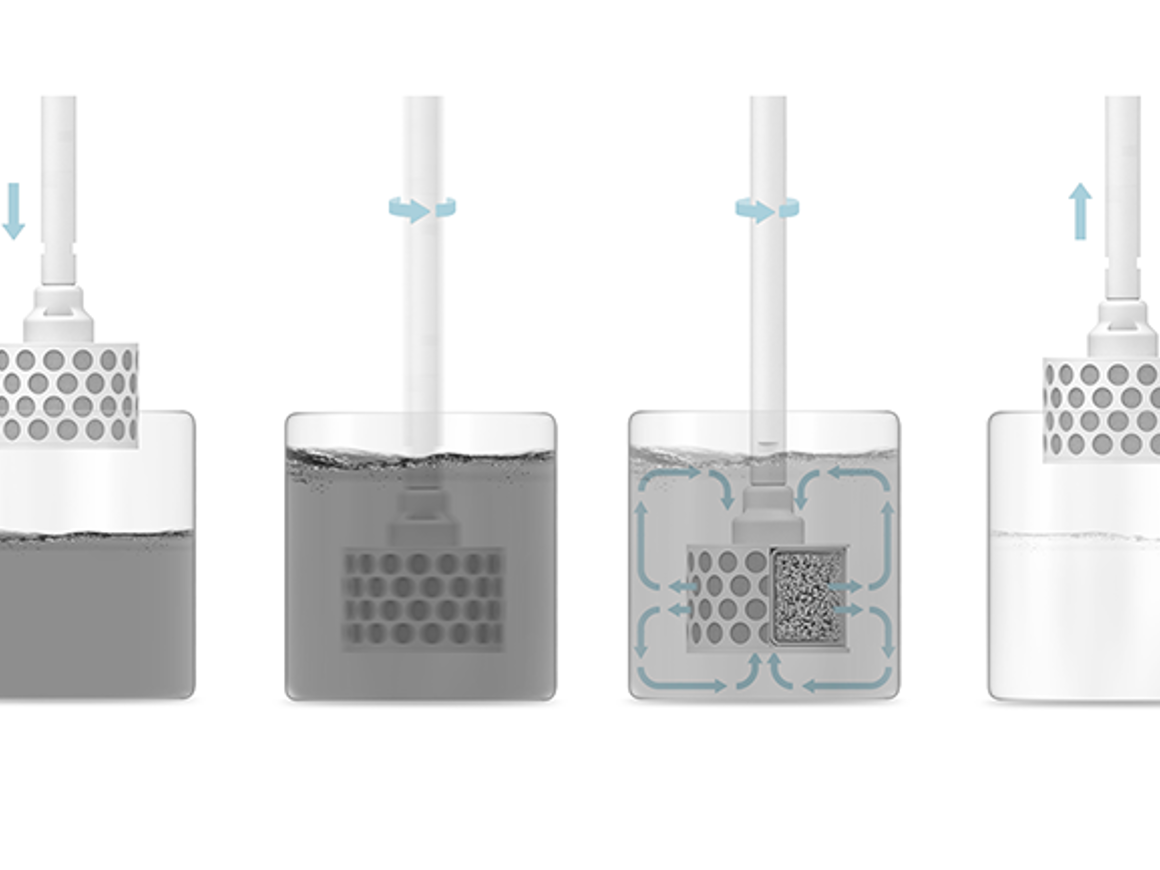

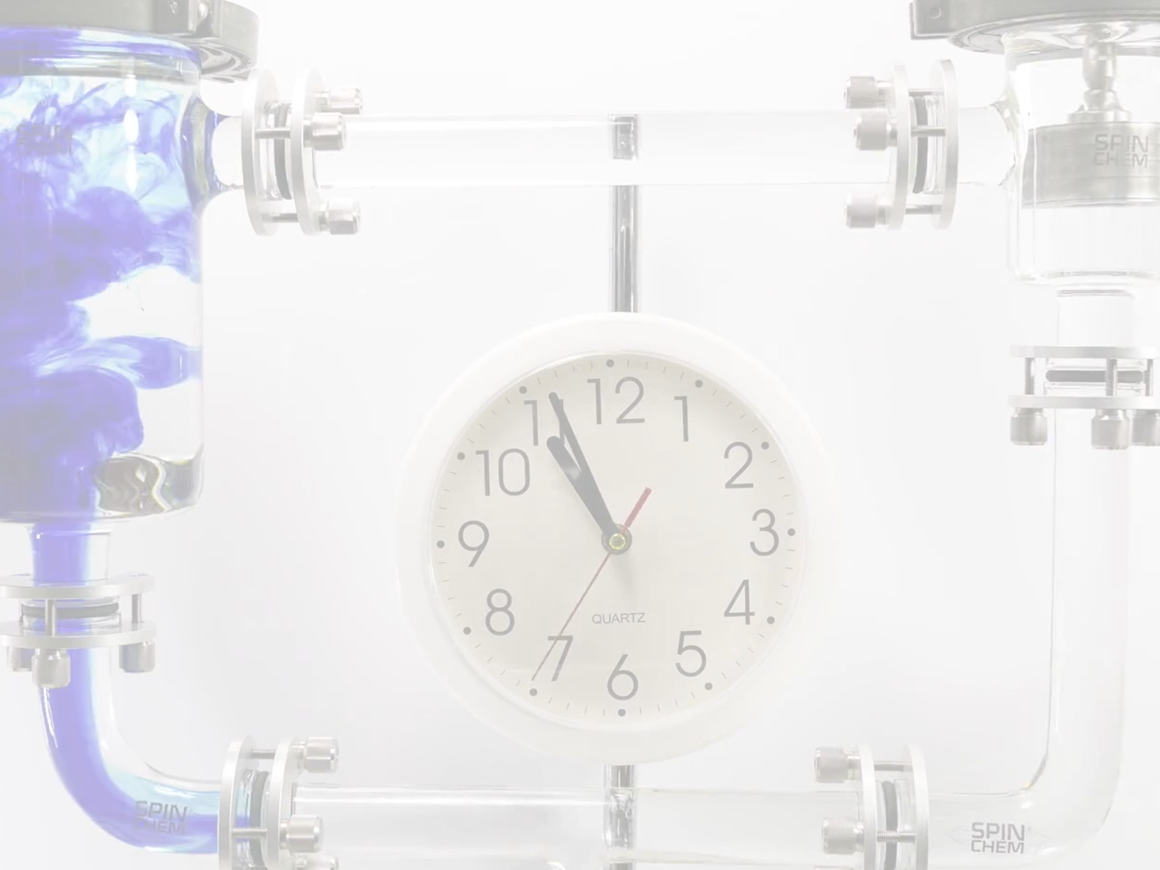

The RBR technology enables to remove radioactive or unwanted elements from wastewater or other fluids, while simultaneously improving the efficiency of the clean-up process through better use of the media. Using the straightforward RBR methodology results in a faster process, higher decontamination factors, and/or reduced generation of secondary waste. In addition, the RBR extends the lifetime of solid-phase particles by minimizing grinding and attrition, while at the same time simplifying the solid phase collection, recycling, or disposal.

Availability in various sizes and volumes

The RBR can range in size from less than one liter to over 100 liters of media (solid phase) capacity depending on application (drums, totes, large tanks, ponds, fuel pools, sumps, or large area basins).

The RBR technology was first used in the pharmaceutical industry to improve chemical processing of liquids. Subsequently, it has found its way into the nuclear industry were it similarly improves processing efficiency. To accelerate the deployment of this technology, SpinChem plans to further mature Spinionic™ into a range of products that address the challenges of nuclear waste treatment.