Downstream processing

The manufacturing of pharmaceuticals, cosmetics and food items consists largely of altering the structure or function of chemicals and chemical compounds. To reach a satisfactory quality of the end-products, there is often also a need for downstream processing, including purification, extraction and polishing. Two solid materials commonly used for such heterogeneous procedures are activated carbon and ion exchangers.

Activated carbon is produced by exposing carbon-rich material to high temperatures under certain conditions; the source material is either pre-treated with chemicals, or exposed to hot gases to achieve a porous structure. The resulting material has a vast surface area (>3000 m²/g) due to the tiny pores having been created between the carbon atoms. The excessive porosity makes activated carbon a suitable material for adsorption, where molecules adhere to a surface by van der Waals forces. Due to this, activated carbon is commonly used in the chemical industry to remove organic impurities in the production of pharmaceuticals and fine chemicals. Other areas of usage include metal extraction, mercury scrubbing, and the purification of various liquids and gases, including polluted water and air.

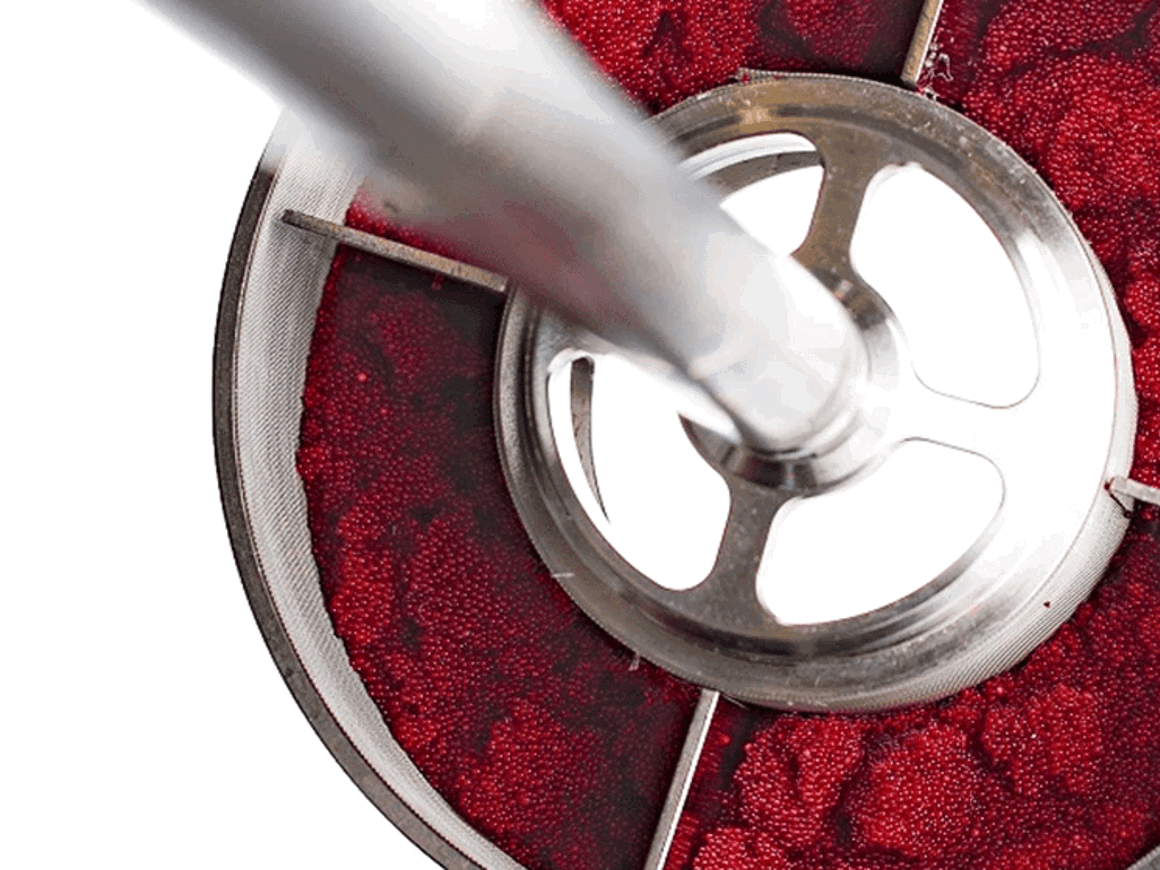

Ion-exchangers are used to purify, separate, decontaminate and catalyse a wide variety of chemical compounds and processes. These polymeric matrices are typically cross-linked into porous microbeads in the size range of 200-500 µm. The properties of ion-exchange resins are determined by the functional groups attached to the internal and external surfaces of the beads. The two most common types of ion exchange resins are anion and cation exchangers, which attract negatively and positively charged ions, respectively. During an ion exchange process, the resin beads acts as a medium to which charged compounds bind, as the loosely bound ions originally attached to the resin are released into the solution. Ion exchangers are not physically altered by the process, and are, by definition, insoluble acids or bases with equally insoluble salts.

Rotating bed reactors

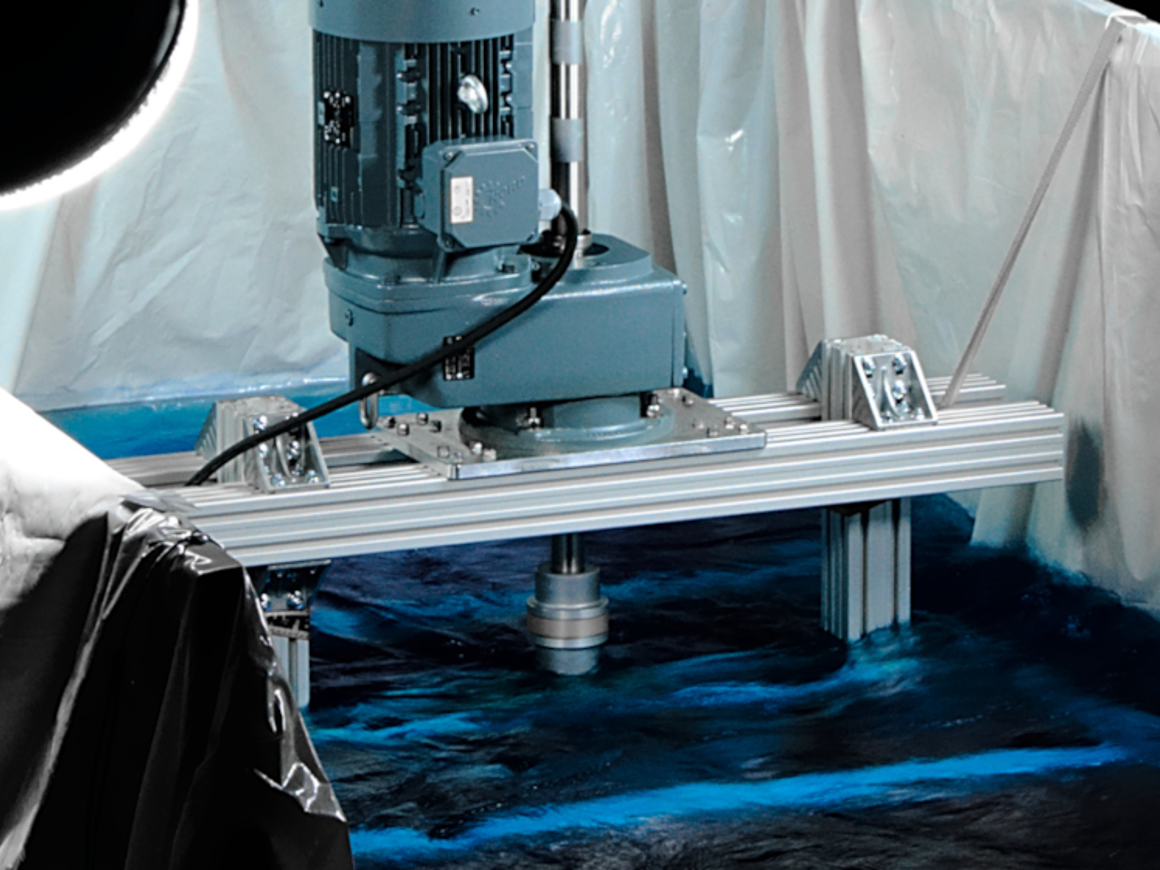

In downstream processing, the soluble compound of interest must come in contact and interact with the solid particles conducting the purification, extraction or polishing. The mass transfer in these cases can be mediated by packed columns, also known as fixed bed reactors (FBR), or by stirred tank reactors (STR). However, these methods have their drawbacks, such as low flow rate, high back pressure, limited mass transfer and mechanical stress on the solid phase particles.

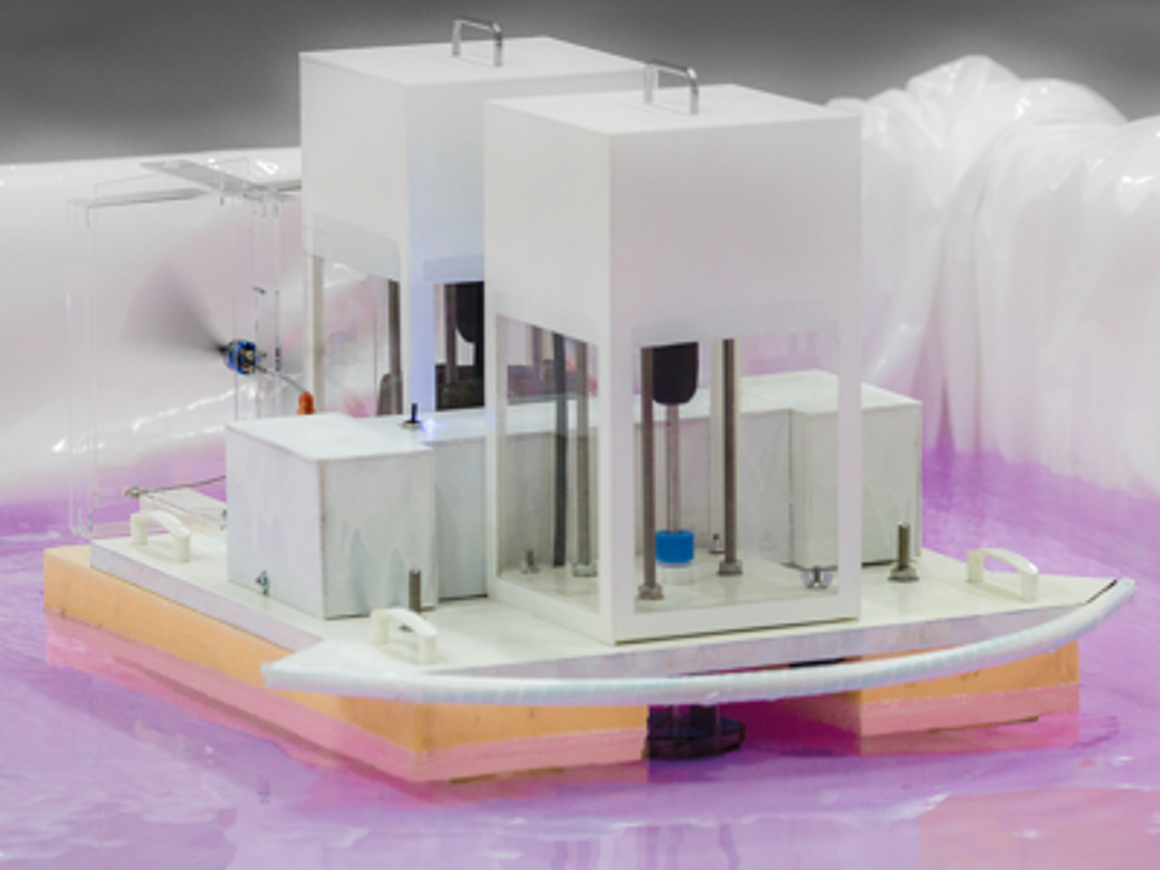

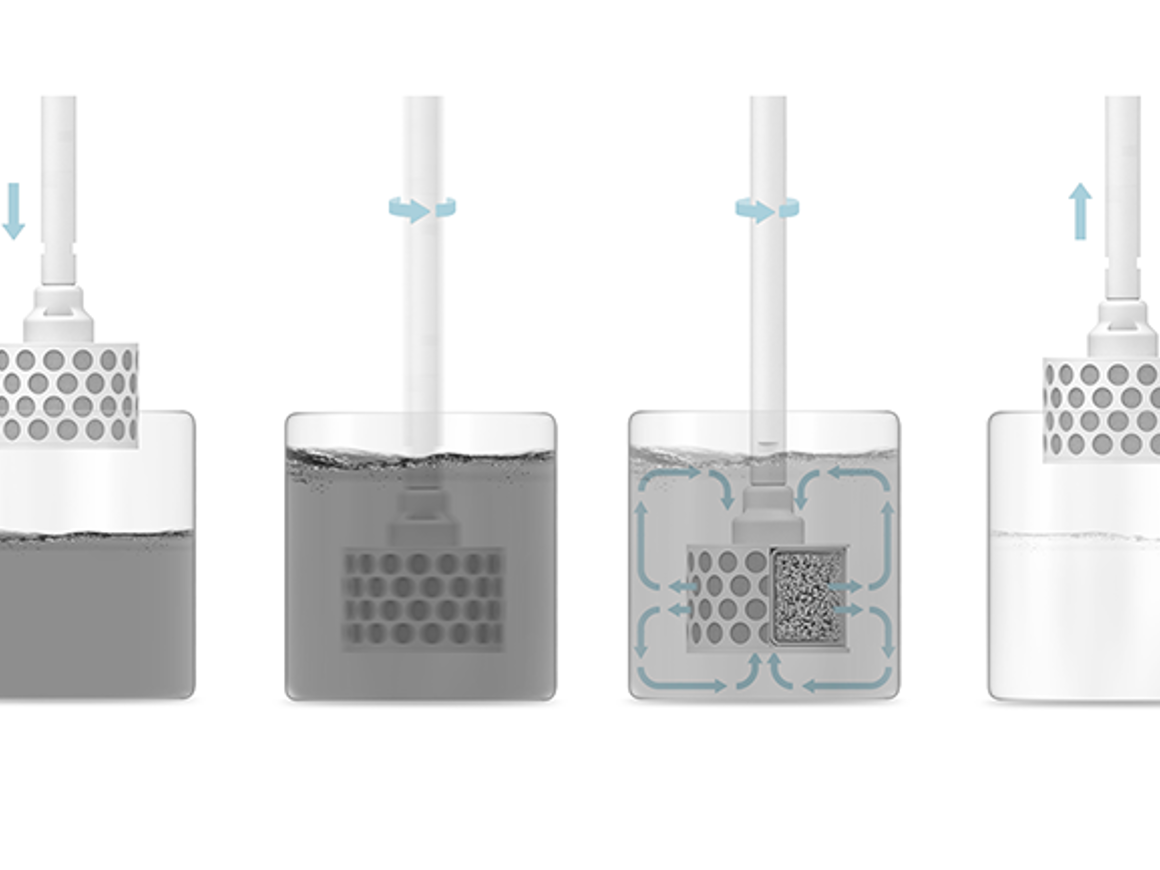

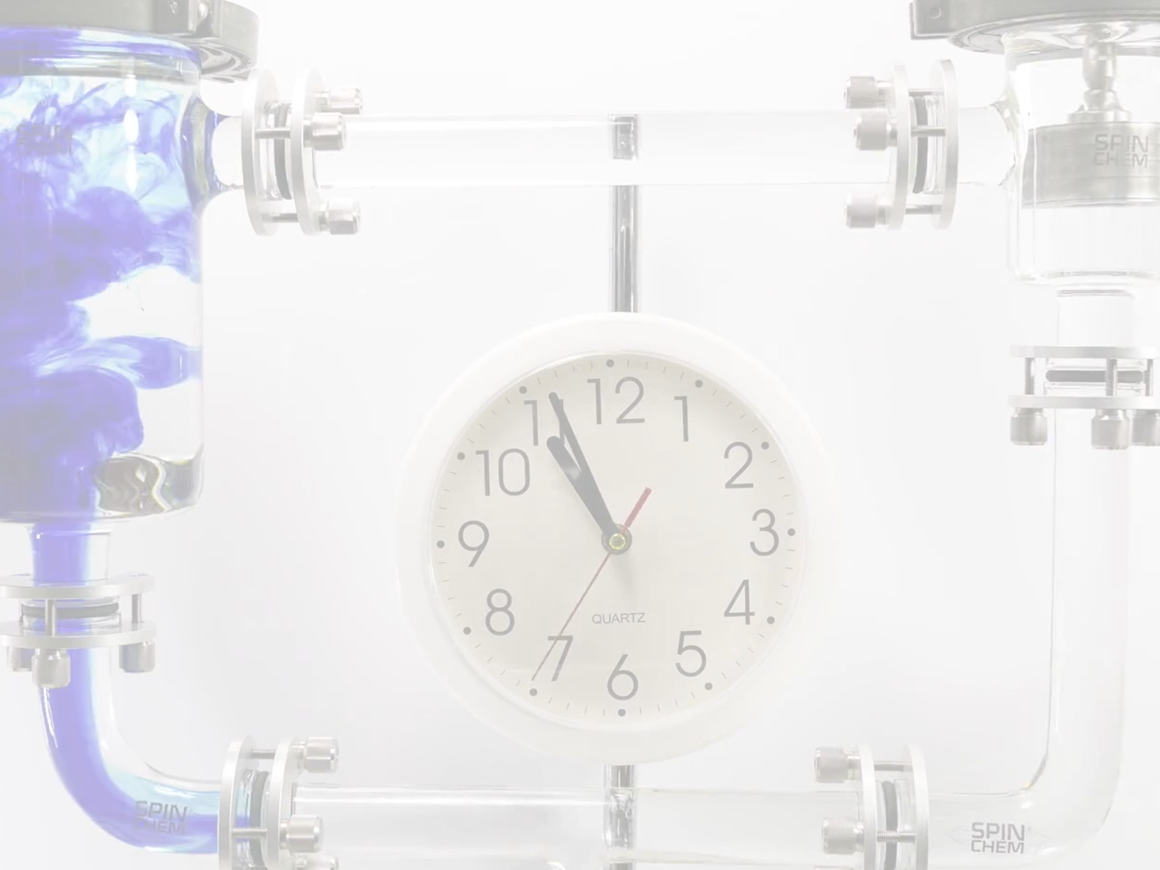

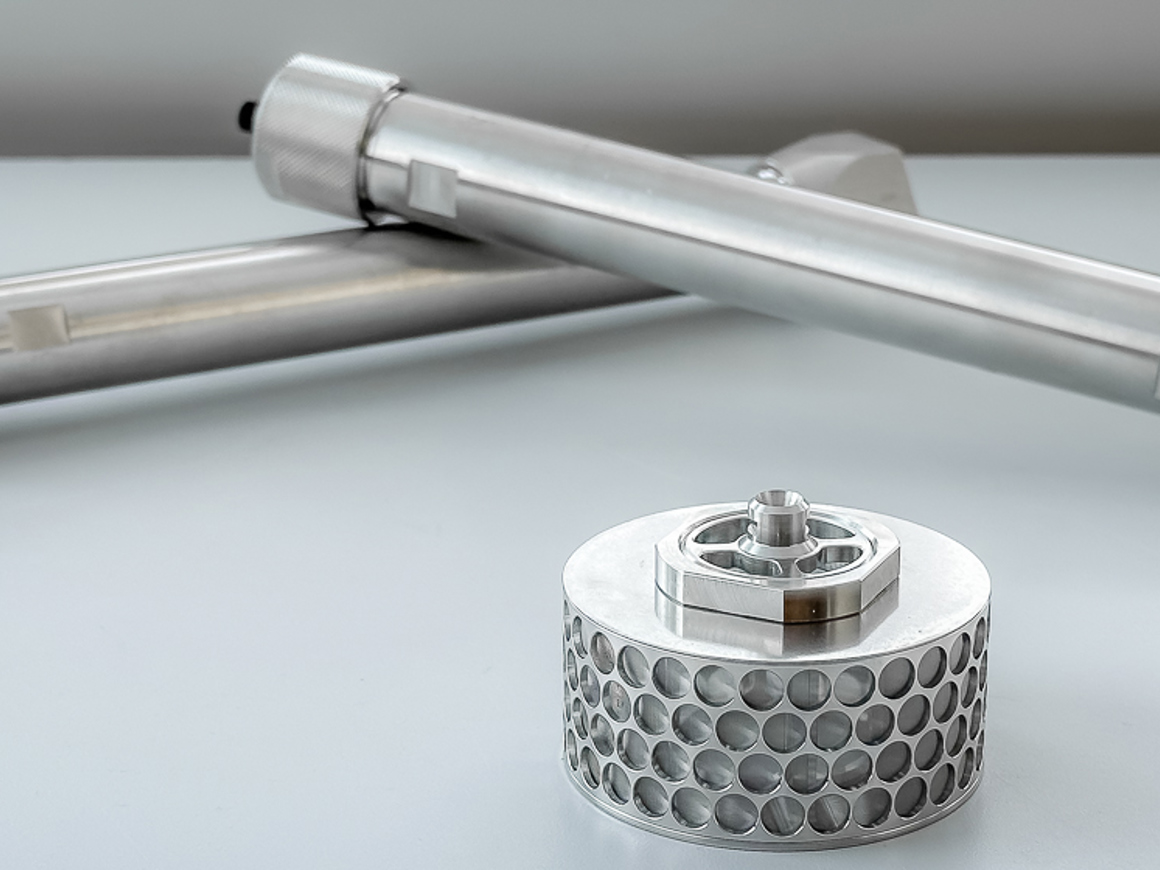

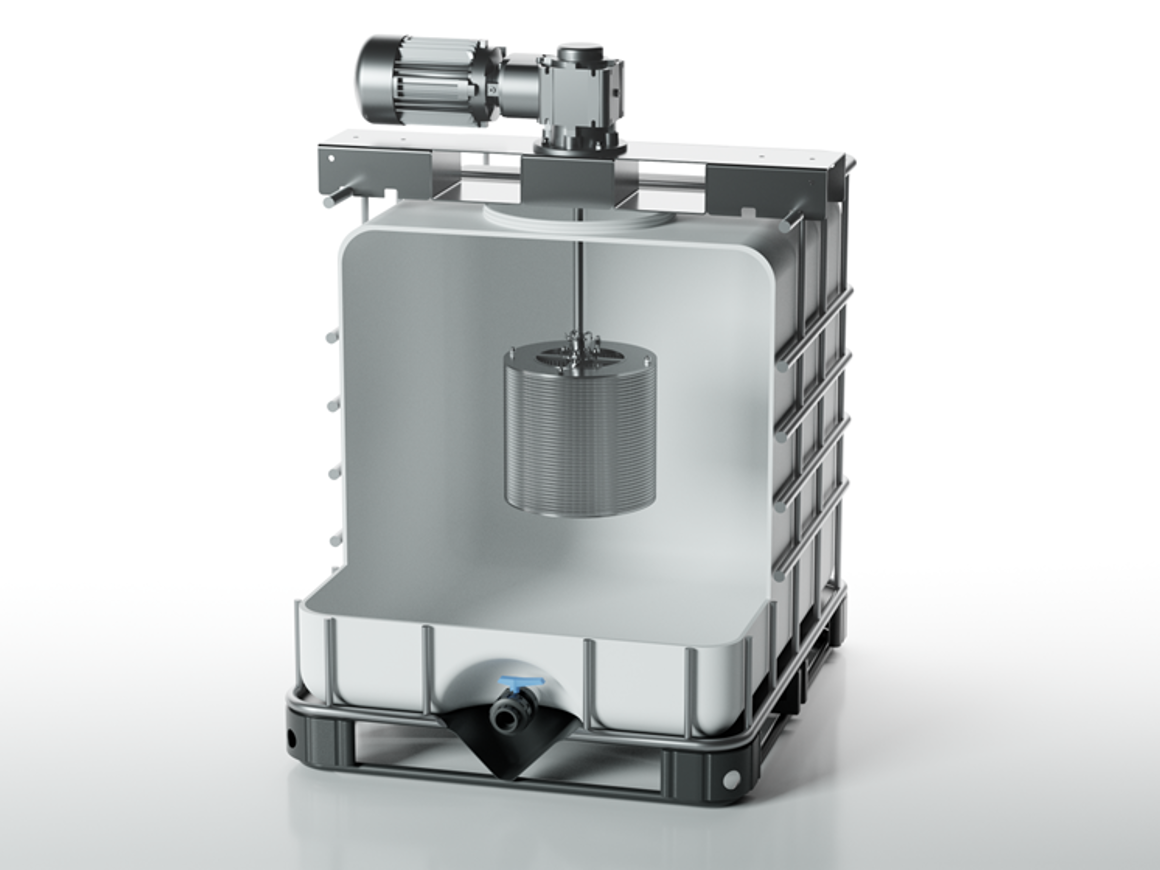

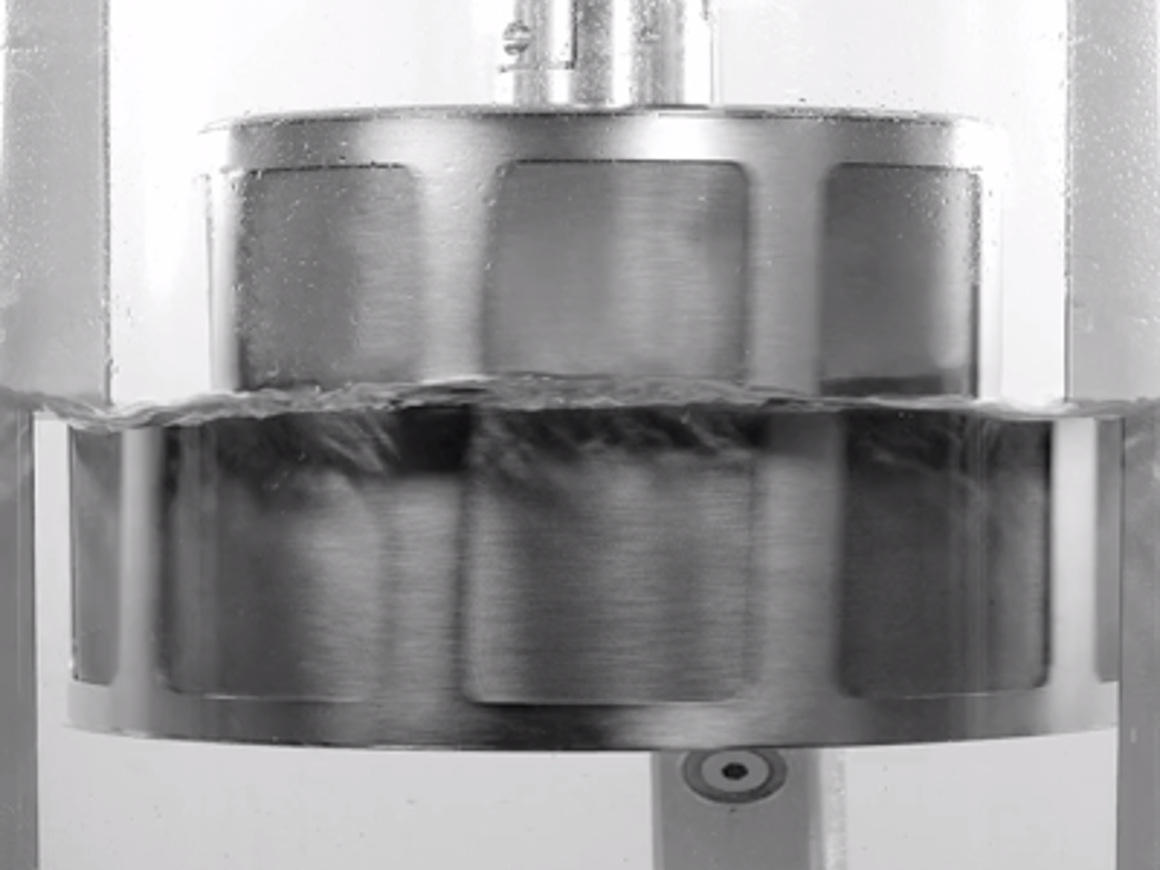

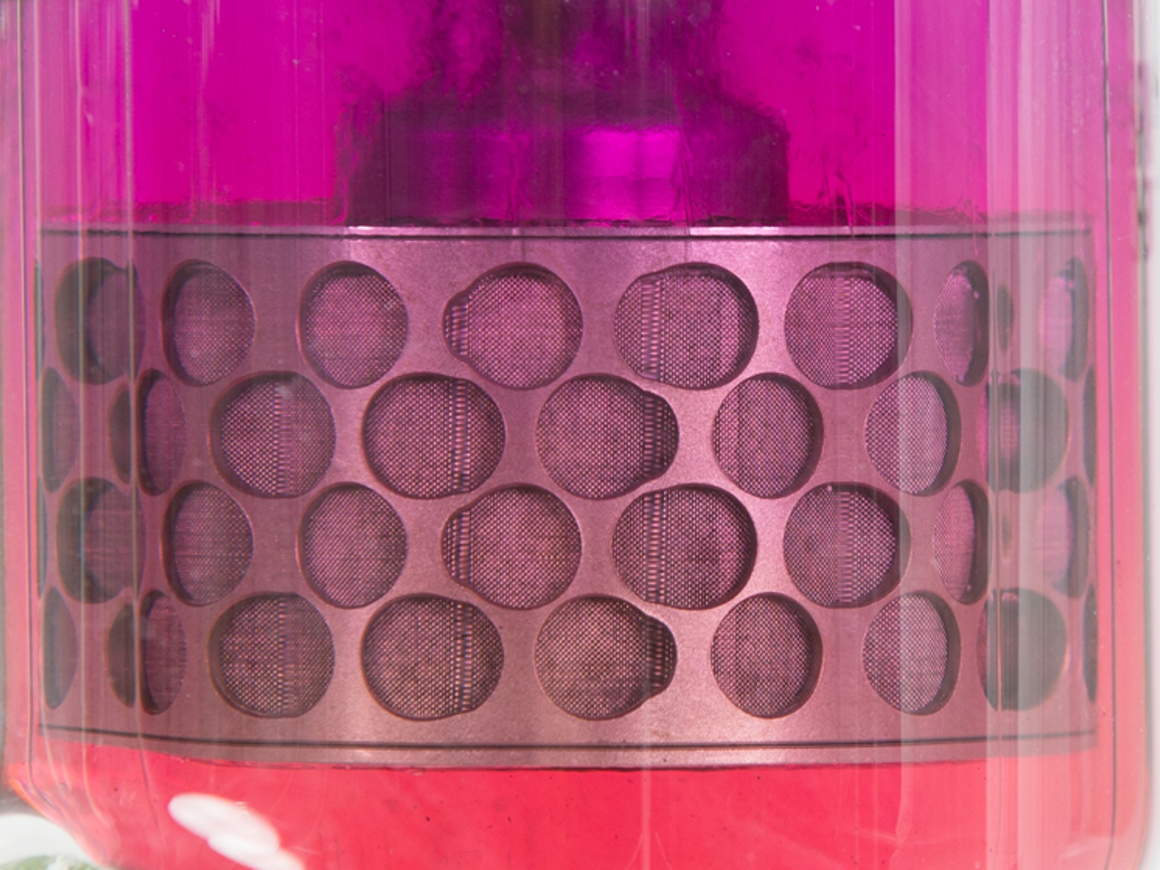

With the SpinChem® rotating bed reactor (RBR), the solid phase is kept inside a rotating stainless-steel cylinder. As the cylinder spins, solution is pushed through the filters of the cylinder and through the packed bed within by centrifugal forces. Simultaneously, new solution enters the cylinder through the centre hole to subsequently be pushed through the bed, thus repeating the process. This allows every liquid parcel to do multiple passages through the bed, optimizing the resin utilization. By increasing the rotational speed of the RBR, the process can be sped up without risking degradation of the solid phase, which is kept well-protected from mechanical forces. The SpinChem® RBR works perfect with ion-exchange resins and granular activated carbon in downstream processing applications. Due to the enhanced mass transfer, the SpinChem® RBR allows for the use of larger, more manageable solid phase particles, without suffering from reduced reaction speed or inferior efficiency.