Immobilized Enzymes for Food Processing

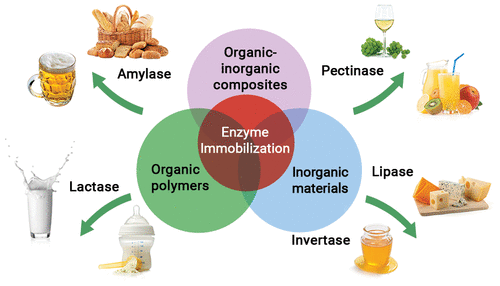

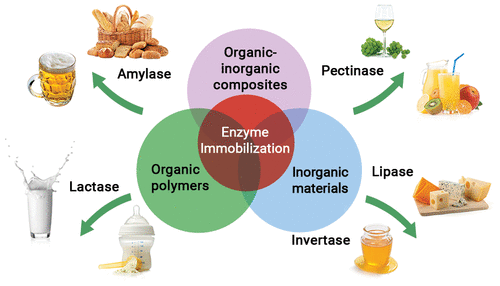

The deepest roots of biological agent-based processing are to be found in the food and feed industries. Nowadays, the use of biocatalytic means has become even more targeted and accessible due to the growing availability of a range of enzymes. These are macromolecular biocatalysts that are often immobilized on inert and insoluble carriers, increasing their efficiency by enabling reuse.

Regarding this, an article was published in the African Farmers Review 2017 which discussed SpinChem's RBR technology and its application with immobilized enzymes in the food industry.

Food processing

Food processing through the use of biological agents is a well established approach. The earliest applications go back to 6,000 BC or earlier, with the brewing of beer, bread baking, cheese and wine making, whereas the first purposeful microbial oxidation dates from 2,000 BC, with vinegar production. The major emphasis of this blog is on the use of immobilized enzymes in the food industry.

The production of high fructose corn syrup is greatly facilitated by the use of immobilized glucose isomerase. Once enzymes are immobilized, many of their operational parameters can be altered. A relatively new concept is the use of a single matrix for immobilizing more than one enzyme. Immobilized multi-enzyme systems offer many attractive advantages. However, associated processes also raise interesting questions regarding reaction kinetics.

Drawbacks of packed column and stirred tank reactors

When using enzymes, a typical approach is to immobilize them on an insoluble material. The obtained heterogeneous preparation is often preferred over soluble enzymes as the solid biocatalyst can be handled and reused more easily, providing technical and economic benefits. During a biocatalytic reaction, the particles carrying the immobilized enzymes may be suspended directly in the reaction liquid, with the substrates transferred between the liquid and solid phase, facilitated by an agitator. This set up is commonly referred to as a stirred tank reactor. Another approach is to keep the solid phase packed into a column through which the liquid phase is pumped through, allowing the soluble substrate to react with immobilized enzymes on the resin. Although often used, these techniques have their own drawbacks, such as incomplete conversions, slow processes, or damage caused to the enzyme particles by the backpressure in the system.

SpinChem's Rotating Bed Reactor

SpinChem is a Swedish chemical engineering company that provides technical solutions that reshape the way process-scale operations are performed. With the latest technology, SpinChem's Rotating Bed Reactor (RBR) enables outstanding catalyst stability in heterogeneous reactions. The liquid processing volume ranges from millimeters to cubic meters. Our goal is to convert your work flow into a simpler, quicker, and less resource-consuming process.

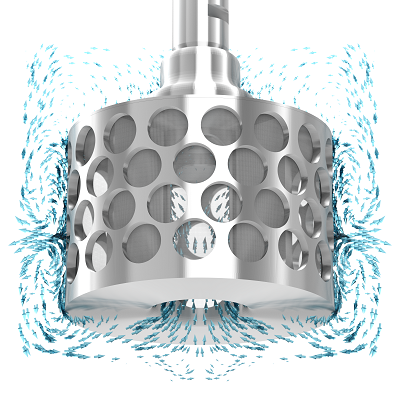

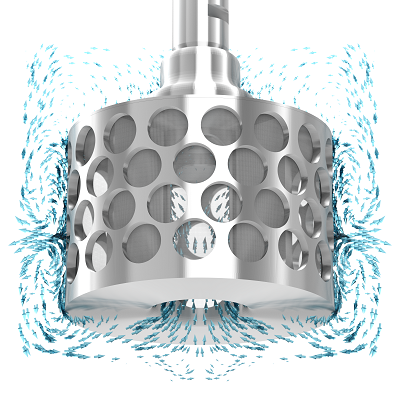

As a resource-efficient solution, SpinChem AB created rotating bed reactors by combining the benefits and removing the disadvantages of packed column and stirred tank reactors. As a modern alternative to stirred tank reactors and columns, this device can be used for a variety of heterogeneous processes, such as absorption and catalysis. In our RBR, the solid phase is kept in the four compartments of a rotating stainless steel cylinder.

SpinChem’s technology - a clever concept

As the RBR spins, the solution is pushed through the filters of the cylinder and through the packed bed within by centrifugal forces. Simultaneously, new solution enters the cylinder from top and bottom to be pushed through the bed, thus repeating the process. This allows every liquid parcel to make multiple passages through the bed, enabling faster processes, higher yields, or reduced reagent consumption.

By increasing the rotational speed of our RBR, processes can be enhanced without risking degradation of the solid phase, since it is kept well protected inside the RBR cylinder. After reaction completion, the RBR containing the solids can easily be washed and reused to process further batches. The fact that the solid phase is kept separated from the bulk liquid and is not exposed to attrition and grinding means that there is no need for filtering or other tedious downstream processing steps to remove particles and fines. This also makes in-line monitoring of the process simple, so there is no reason particles should be in contact with the probe to disturb the readings.

The ingenious design of the RBR enables seamless stability, allowing the technique to be used for heterogeneous reactions in liquid volumes at every scale, from lab work to full production. By constant product development and through close cooperation with international customers and specific instructions. SpinChem AB offers the solution for everything from the production and refinement of pharmaceuticals, cosmetics, and food items to biodiesel synthesis and water purification, always working to ensure both time and resource-effective workflows.

Interested in the rotating bed reactor?

Let SpinChem help you understand how the rotating bed reactor technology can simplify or improve your process. Get in touch with us today to get started towards better, more efficient biocatalysis.