Is your Rotating Bed Reactor due for Service?

Although our systems are designed to last, spare parts wear out with intensive use and time. As is true for most things in life, some love and attention is required to uphold excellence. Is it time to give your system some new spare parts and maintenance?

Essential replacement parts for optimal Rotating Bed Reactor performance

For optimal performance, we recommend regularly replacing these consumables:

Filter kits

Filters are intended for single use only. While they can be washed and reused if handled with care, filters should be replaced when they begin to change shape or fray to prevent leakage in or out of the packed bed.

Select the appropriate filter kit for your system: Filter Kit S2 for the RBR S2 models, or Filter Kit S3 for the RBR S3 model.

You can place an order or purchase directly from our webshop.

Identifying and resolving common problems

Are you experiencing other issues? Please find some of the most common issues that users face and how to address them with our replacement parts and services outlined below:

Are particles leaching from your RBR?

Ensure that the particle size of the solid phase (catalyst, adsorbent, etc.) deployed in the RBR matches the specifications of >100 µm. If you still encounter particle leakage, try to exchange your filters.

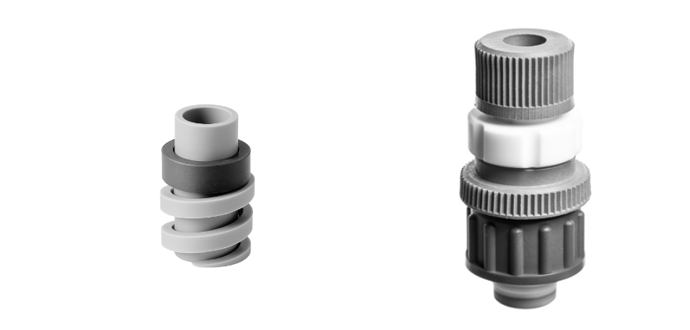

Headspace headaches?

If you're having trouble applying vacuum to the reactor, or if solvent vapours are escaping the vessel, it could be time for a new PEEK seal for your shaft guide.

If running your process under vacuum and consistently hight RPM the entire shaft guide will need replacing from time to time as well as the seal for the vessel.

Let us know if you have any challenges in controlling the atmosphere in the reactor.

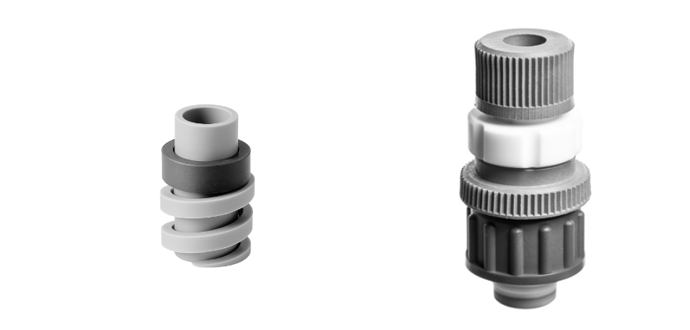

Trouble with leakage from the bottom valve?

Is the piston tough to close, or it won't seal properly? Don't risk damaging your glassware. It is quick and easy to replace the o-ring in the tip of the bottom valve.

If the piston is damaged a full replacement is required.

Cracked glassware? Noise coming from the motor?

We keep laboratory equipment in stock and can replace damaged or defective items in a few business days. Reach out to us for a trouble shooting discussion of what may be required.