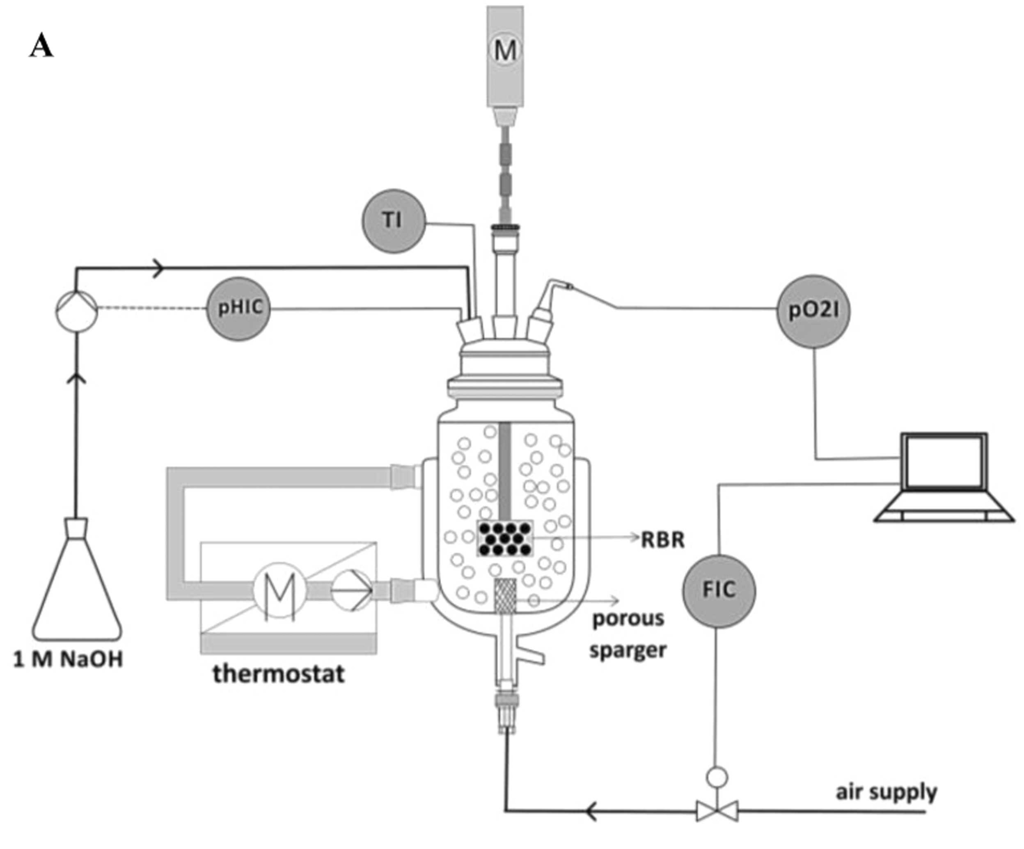

"The utilization of oxidases suffers from insufficient oxygen availability due to its low solubility in gas-liquid multiphase systems. To overcome this limitation, oxygen is continuously supplied to the reaction medium during the course of the reaction, however, it causes significant gas consumption. In this study, a novel experimental set-up was established by installing a sintered frit porous sparger in the SpinChem® rotating bed reactor. Covalently immobilized glucose oxidase on epoxy-functionalized carriers was used in the rotating bed reactor with an activity yield of the immobilization of over 98%. For fine bubble aeration, the volumetric mass transfer coefficient kLa (67.3 h− 1) tripled compared to macrobubble aeration (22.5 h− 1), while the volume-specific aeration rate remained constant. A maximum reaction yield of 96.5% was reached. The reaction rate was improved by a factor of 12.9 for the fine bubble aeration compared to macrobubble aeration under identical conditions. With fine bubble aeration, the oxygen consumption was reduced by 87.5% over macrobubble aeration, establishing the same enzyme-specific reaction rates at a comparable kLa. Validation was carried out in repetitive batches, achieving the same glucose oxidase specific activity. This study demonstrates the advantages of fine bubble aeration and presents promising results for addressing sustainable biotransformation processes."

Highlights:

The study examines a new approach using fine bubble aeration in a SpinChem® rotating bed reactor to improve biocatalytic oxidation by enhancing oxygen availability. This technique not only improves reaction yield significantly but also achieves a 12.9-fold increase in reaction rate while reducing oxygen consumption by 87.5% compared to traditional macrobubble aeration methods. Fine bubble aeration thus offers a promising solution for sustainable bioprocess intensification.

- Enhanced Oxygen Transfer: Fine bubble aeration in the RBR significantly improves oxygen availability by increasing the volumetric mass transfer coefficient (kLa), which is crucial for biocatalytic reactions with low oxygen solubility.

- Imptoved Reaction Rate and Yield: The RBR with fine bubble aeration achieved a 12.9-fold increase in the reaction rate compared to macrobubble aeration under identical conditions.The setup achieved a maximum reaction yield of 96.5%, demonstrating efficient process intensification.

- Reduced Oxygen Consumption: Fine bubble aeration reduced oxygen consumption by 87.5% compared to macrobubble aeration, leading to more sustainable operations.

- Effective Immobilization: The RBR design allows for the covalent immobilization of enzymes on epoxy-functionalized carriers, achieving an activity yield of over 98% and enabling enzyme reuse.

- Repetitive Batch Capability: The RBR enables repetitive batches with consistent glucose oxidase-specific activity, making it suitable for prolonged and stable operations.

- Sustainable Process Solution: This configuration provides a promising, scalable approach for sustainable biotransformation processes by optimizing oxygen usage and reducing energy consumption.