Clean and pure: Our commitment to removing pesticides from your products

All types of oils can potentially contain pesticides, as pesticides are often used in agriculture to protect crops from insects, diseases, and other pests. Oils that are derived from crops that are commonly treated with pesticides, such as vegetable oils and fruit oils, are more likely to contain pesticides than oils derived from other sources.

Common oils that may contain pesticides:

- Vegetable oils: Vegetable oils, such as soybean oil, corn oil, and canola oil, are often derived from crops that are treated with pesticides to protect against pests and diseases. These oils may therefore contain residues of pesticides.

- Fruit oils: Fruit oils, such as citrus oil, olive oil and avocado oil, are also often derived from crops that are treated with pesticides. These oils may therefore contain traces of pesticides.

- Animal oils: Animal oils, such as lard and tallow, may also contain pesticides if the animals were exposed to pesticides through their feed or the environment.

- Essential oils: Essential oils, which are extracted from plants using steam distillation or other methods, may also contain pesticides if the plants were treated with pesticides.

Overall, any type of oil can potentially contain pesticides, and it is important to carefully check the source and quality of the oil to ensure that it is free of pesticides.

Reasons to remove pesticides from extracts and oils:

- Pesticides can be harmful to human health.

- Pesticides can affect the quality of extracts and oils.

- Pesticides can be harmful to the environment.

- Pesticides can lead to legal and regulatory issues.

Methods for removing pesticides from oils: adsorption, extraction, and chemical degradation

There are several methods that can be used to remove pesticides from oils, depending on the specific type of pesticide and the characteristics of the oil. Some of the key methods for removing pesticides from oils include the following:

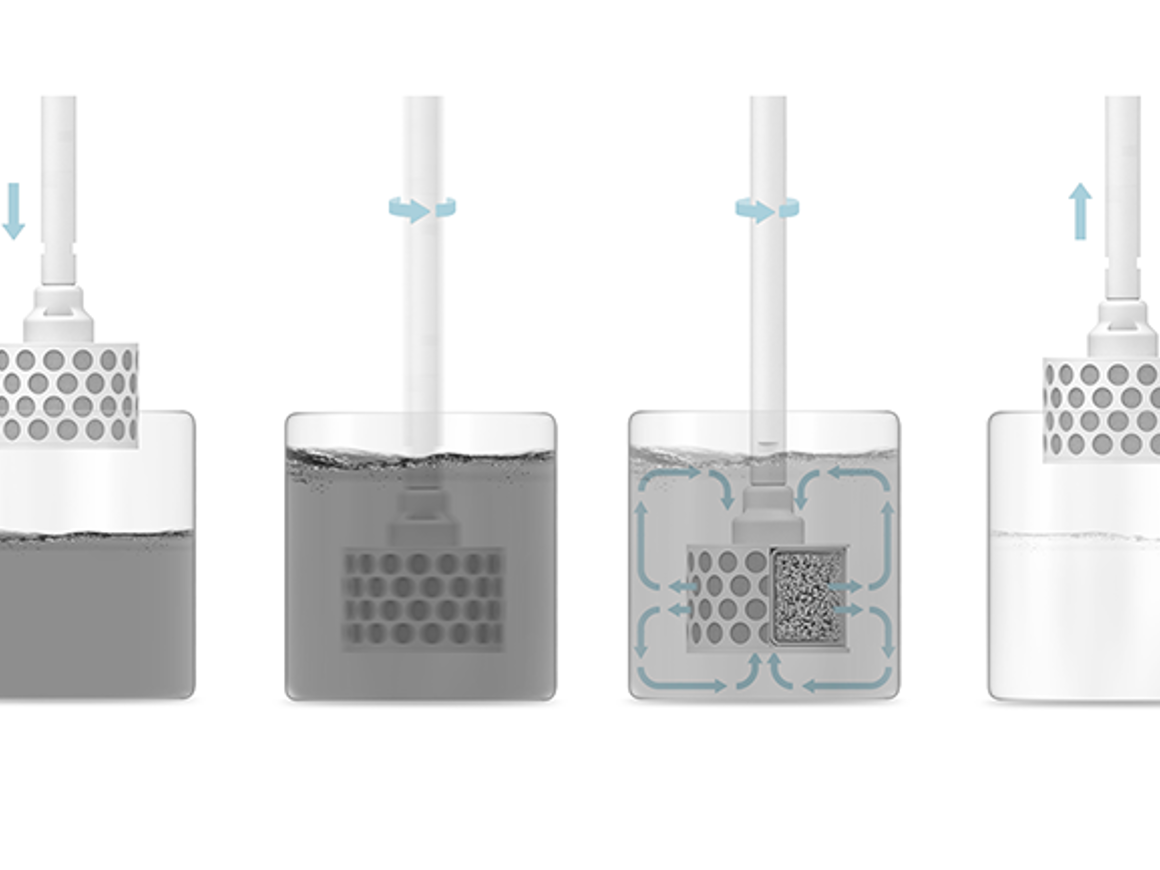

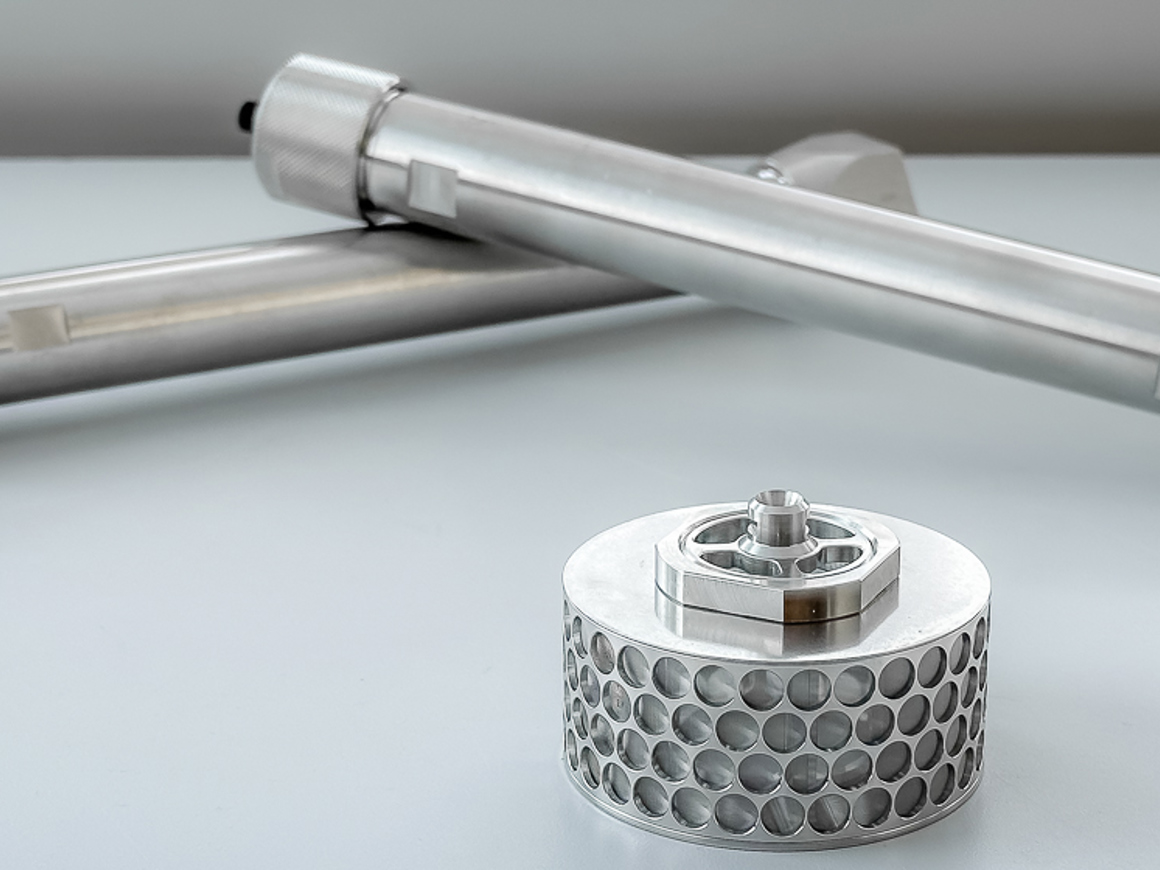

- Adsorption: Adsorption is a process in which pesticides are removed from the oil by binding to a solid adsorbent material, such as activated carbon or clay. The adsorbent material is mixed with the oil, and the pesticides are attracted to the surface of the adsorbent, where they are retained. The adsorbent material can then be removed from the oil using filtration or centrifugation.

- Extraction: Extraction is a process in which pesticides are removed from the oil by mixing the oil with a solvent, such as hexane or ethanol. The solvent dissolves the pesticides, which are then separated from the oil using techniques such as distillation or filtration.

- Chemical degradation: Chemical degradation is a process in which pesticides are broken down into smaller, less toxic compounds using chemical reactions. This can be achieved using a variety of chemicals, such as oxidizing agents or enzymes, depending on the specific type of pesticide.