Enzyme Immobilization Solutions: ChiralVision's Expertise in the Enzyme Technology Alliance

Many chemical manufacturers face significant challenges in their biocatalytic processes. Traditional enzyme methods can be costly due to enzyme instability, low reusability, and difficult separation from products. Additionally, companies struggle with scaling up enzymatic processes while maintaining efficiency and meeting economic targets. Process development teams often grapple with finding the right enzyme immobilization solutions that can deliver both technical performance and economic viability.

Companies in pharmaceutical, food, and fine chemical industries need reliable enzyme technology partners who can help them:

- Improve enzyme stability and reusability

- Simplify downstream processing

- Scale up biocatalytic processes efficiently

- Reduce production costs

- Meet sustainability targets

We at SpinChem interviewed members of the Enzyme Technology Alliance (ETA) to get their perspective on modern ways of handling biocatalysis.

Meet ChiralVision – Experts in Smart Biocatalysis

ChiralVision is a Dutch company focused on making chemical processes more efficient and sustainable through smart enzyme technology. They specialize in enzyme immobilization, helping companies get the most out of their enzymes by making them more stable, reusable, and easier to work with.

Whether you're developing a new biocatalytic process or looking for the right enzyme carriers, ChiralVision offers practical solutions and ready-to-use immobilized enzymes tailored to your needs.

With years of hands-on experience and a passion for innovation, they’re helping industries move toward greener, more cost-effective production.

SpinChem: What role does ChiralVision have in the Enzyme Technology Alliance?

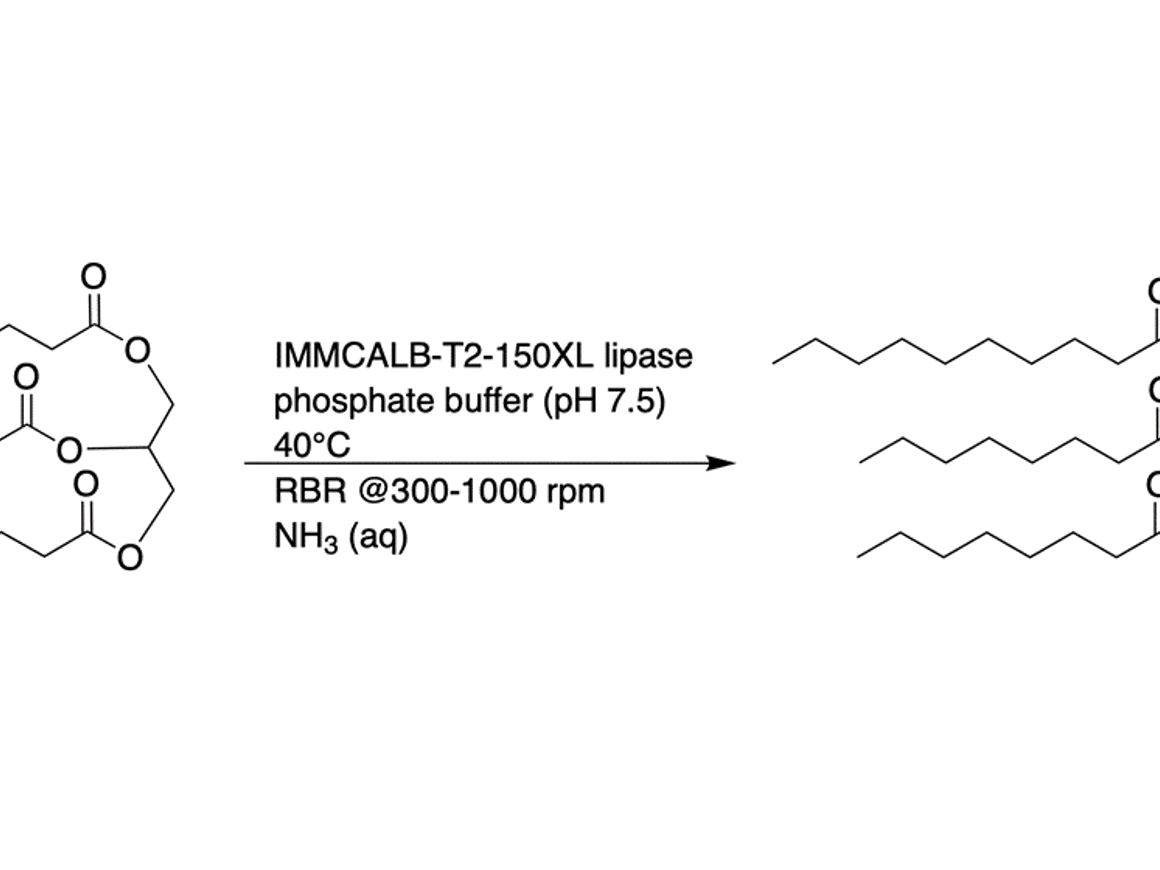

Dr. Rob Schoevaart: "As a founding member of the Enzyme Technology Alliance (ETA) ChiralVision plays a pivotal role by contributing its specialized expertise in enzyme immobilization and biocatalytic process development. Established in 2006 and headquartered in the Netherlands, ChiralVision focuses on developing and producing enzyme carriers, immobilized enzymes and chiral molecules. Utilizing various carrier materials ranging from classic acrylic polymers to silica and renewable cellulose we facilitate economical viability and sustainability of biocatalytic production processes across multiple industries, including pharmaceuticals, life sciences, cosmetics, food, feed, biofuels, and environmental applications.

Within the ETA, ChiralVision collaborates with other biotech SMEs—Candidum, Aminoverse and Enzymicals to take new enzymes from R&D to chemical manufacturing. ChiralVision's role is integral to the ETA's mission of providing tailor-made enzyme solutions, driving innovation, and promoting sustainable industrial processes through advanced biocatalysis technologies.

ChiralVision has designed and produces custom immobilized enzyme formulations, has proven industrial applications for hydrolysis, oxidation, reduction, esterification, transesterification, and chiral resolutions. We provide rapid prototyping and feasibility screening for your specific substrates. If your process requires stable, reusable enzymes, ChiralVision can provide tailored solutions."

SpinChem: Why should you meet with the Enzyme Technology Alliance and ChiralVision at Biotrans?

Dr. Rob Schoevaart: "Meeting us opens the door to comprehensive Biocatalysis Expertise. See real examples of how ETA's enzyme solutions were deployed in industry and ask technical questions directly to the scientists and developers. Discuss potential collaborations, feasibility studies, and custom enzyme screening.

Where our partners bring together the full enzyme value chain from in silico enzyme discovery and AI-supported protein engineering ChiralVision offers Immobilization technologies, Process development and scale-up. You get access to end-to-end solutions for enzymatic processes in pharma, food, fine chemicals, and industrial biotech.

If you're looking to innovate with enzyme technology, improve process efficiency, or explore biocatalytic routes for your molecules, meeting ETA and ChiralVision at Biotrans is a strategic move. It’s where research meets industrial application—and where you can find partners to bring your enzymatic ideas to life."

SpinChem’s perspective: what makes our combined approach in biocatalysis unique?

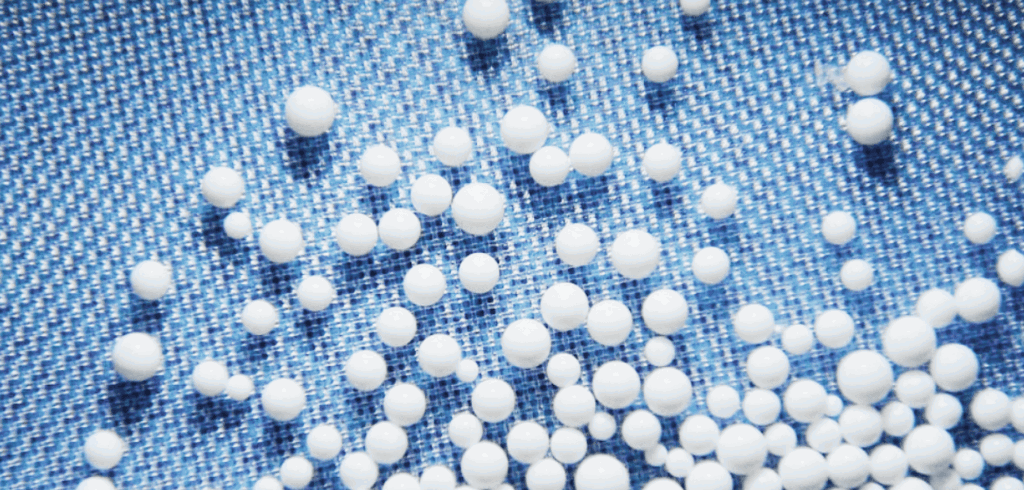

Working together within the Enzyme Technology Alliance (ETA), SpinChem and ChiralVision offer end-to-end solutions for enzymatic process development. From selecting the right enzymes and carriers to optimizing reaction conditions in the RBR, our combined expertise helps customers achieve more sustainable and efficient biocatalytic processes.

The SpinChem RBR technology creates ideal conditions for immobilized enzymes by providing:

- Gentle treatment of carriers extending their lifetime

- Enhanced mass transfer between enzymes and substrates

- Easy separation of immobilized enzymes from reaction media

- Simplified scale-up from laboratory to industrial production