Environmental

Efforts are made in all directions to reduce humanity's negative impact on the environment by consuming fewer of the planet's resources, re-using the resources already extracted, using more energy- and material-efficient production techniques, releasing less waste back into nature, and making better efforts to undo damage and remediate pollution.

One challenge in managing liquid waste is aging infrastructure, which creates a growing need for innovative solutions to treat polluted liquids and manage waste effectively.

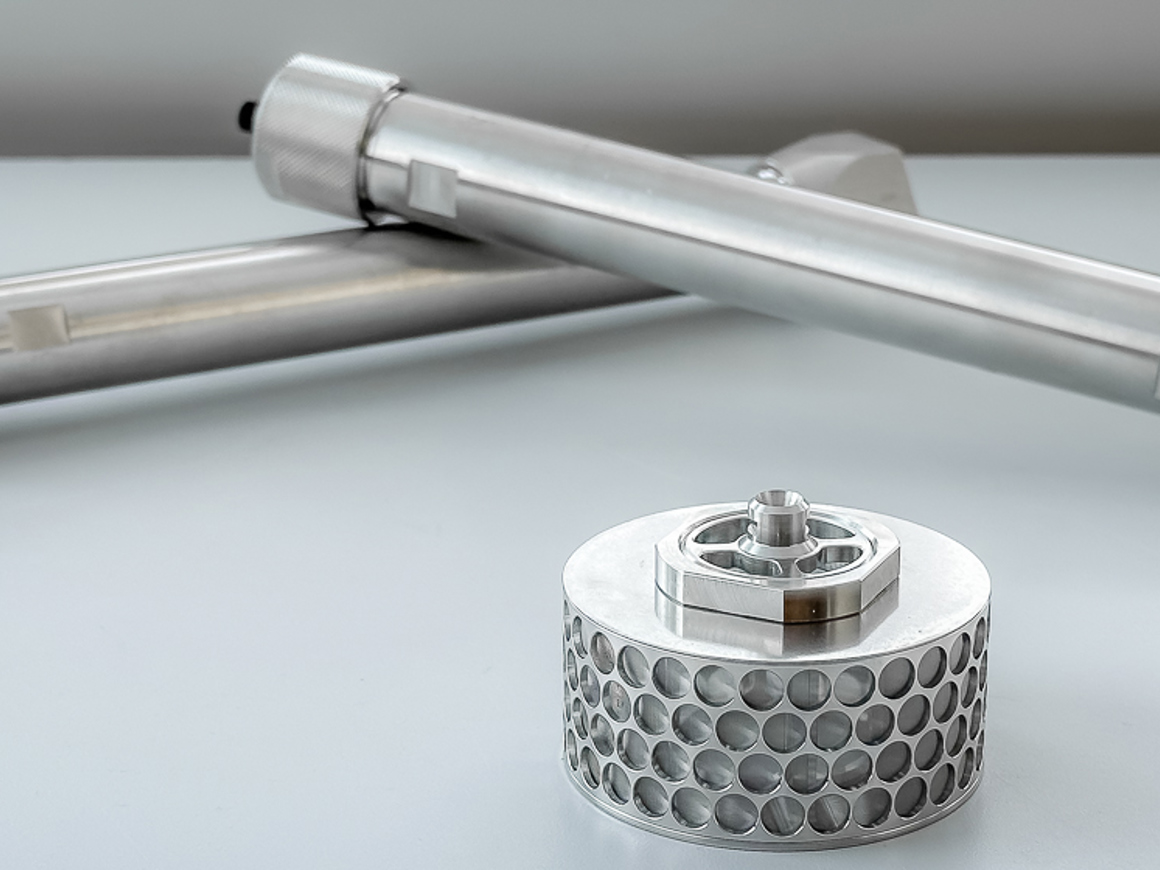

At SpinChem, we prioritize environmental issues and strive to contribute. The rotating bed reactor (RBR) can help in several ways, including:

- Using sustainable approaches like biocatalysis for production

- Enhancing energy and material efficiency

- Minimizing resource consumption and waste production

- Reusing and recycling resources

- Transitioning away from fossil fuels and decarbonizing the economy

Managing Large Volumes of Waste More Effectively

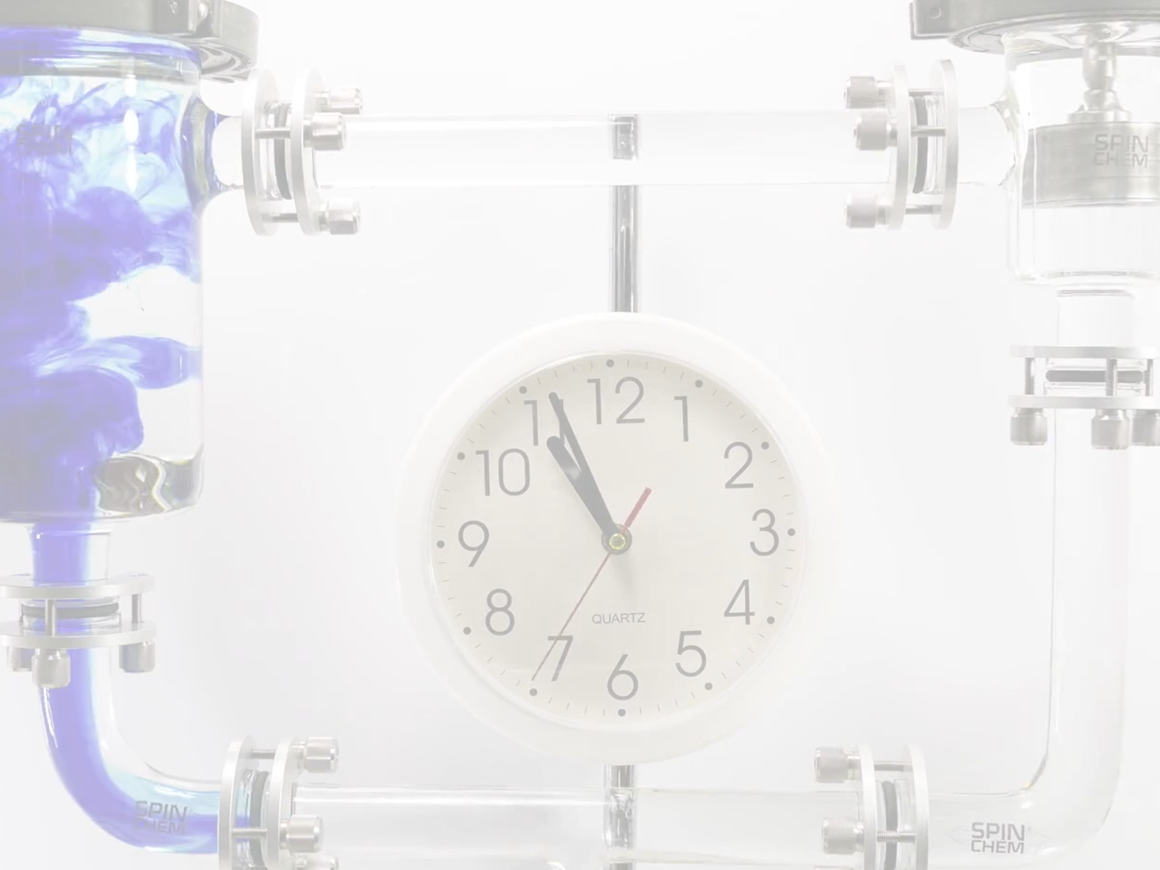

Large volumes of liquid waste often accumulate at industrial sites. Treating these waste streams adequately can be time-consuming and resource-intensive, often compounding the problem over time.

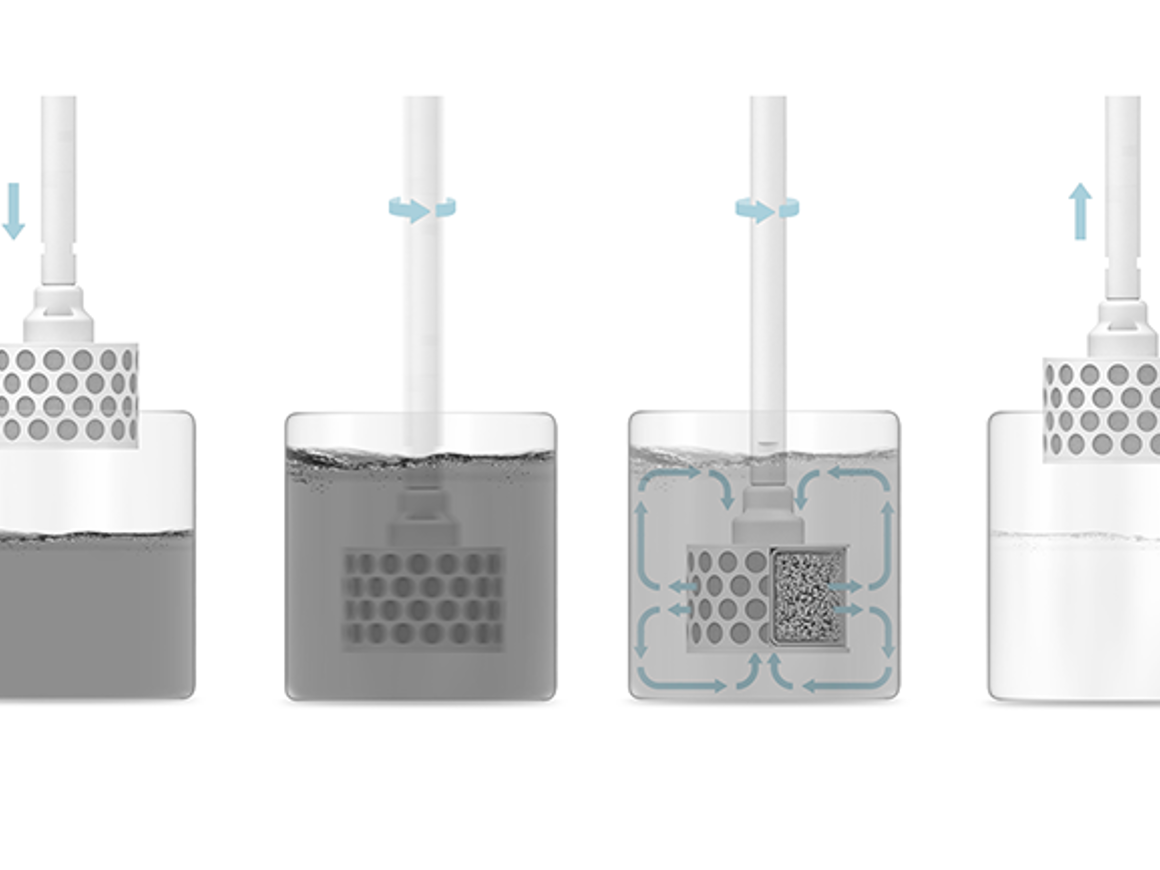

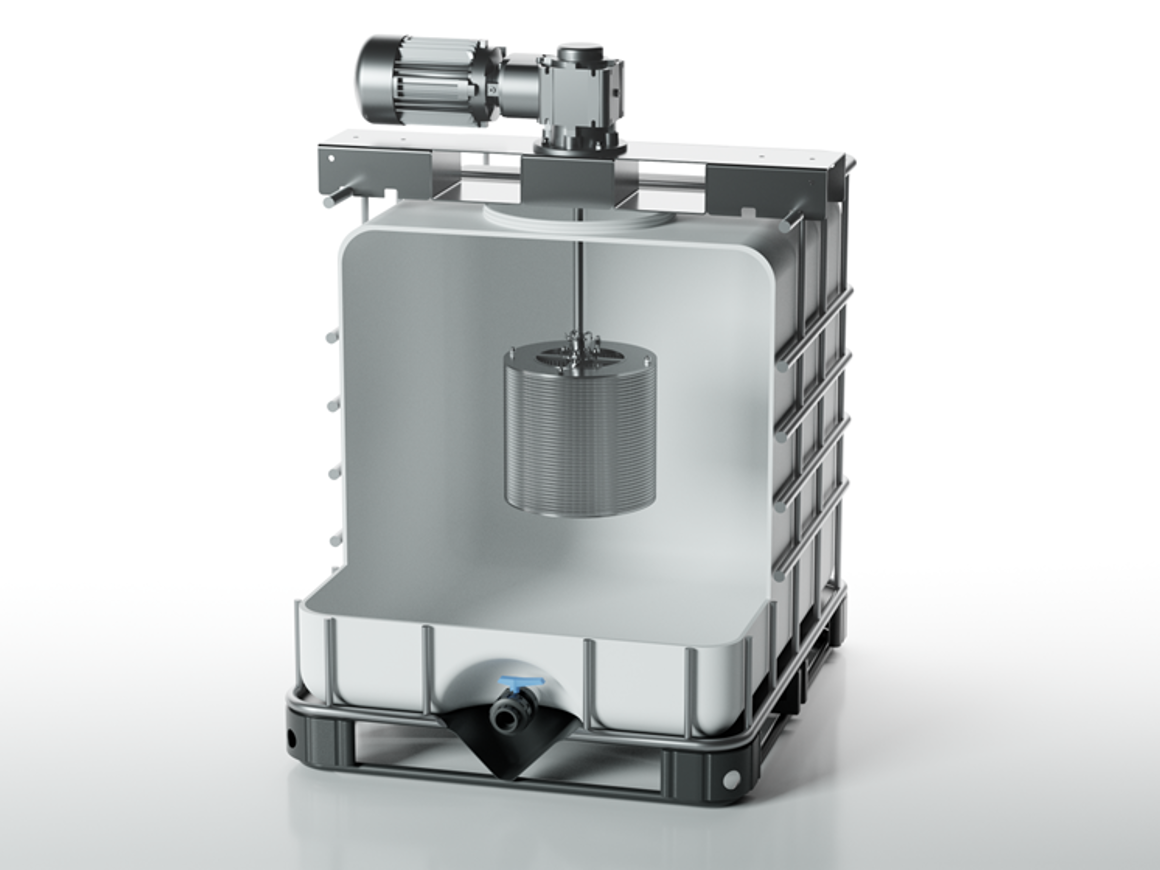

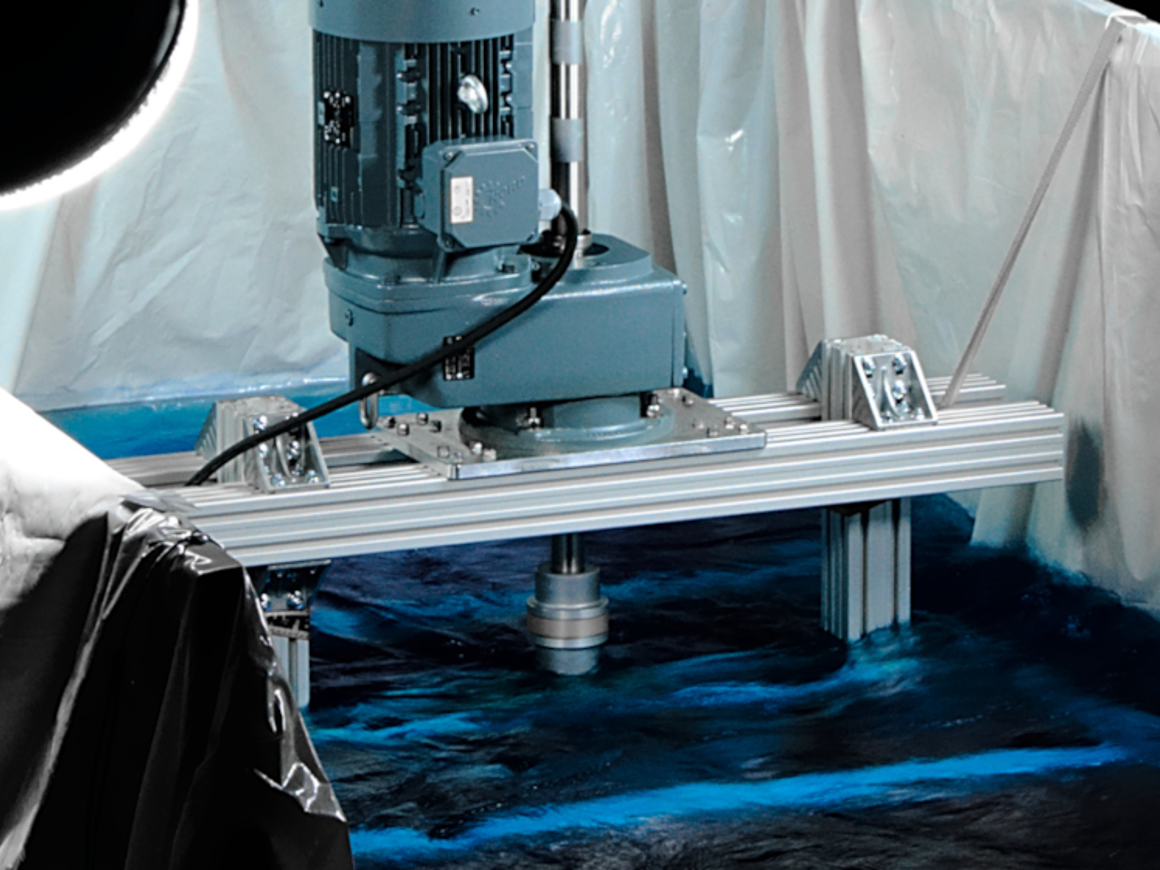

RBR is a tool for treating large volumes of liquids, either to produce valuable batches of a product or to treat problematic liquid waste. In the latter case, contamination is concentrated into a smaller volume of solid waste, often reducing the mass and volume of the waste by thousands of times.

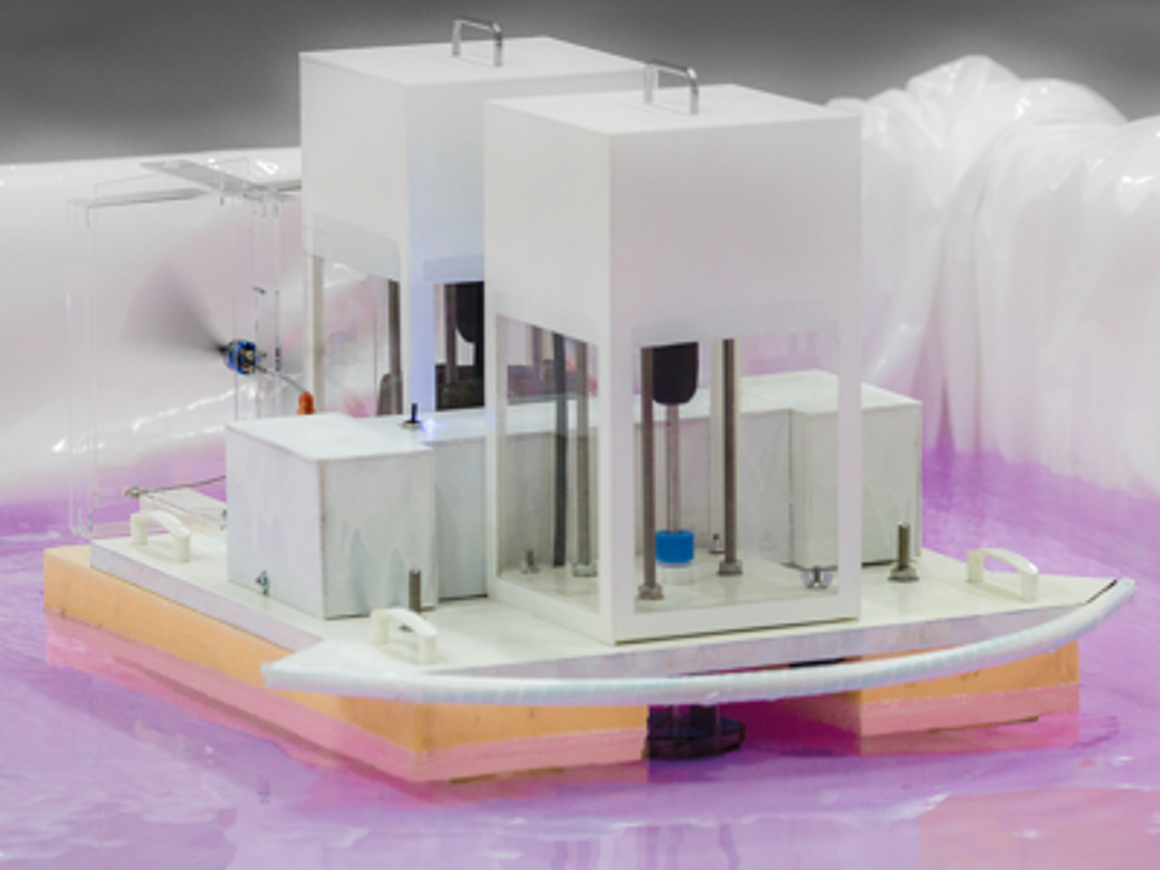

At SpinChem, we design treatment systems for individual cases and requirements. We can build and test complete systems and predict performance using computational models and in-house pilot tests.

As an example, legacy waste in the nuclear industry, unresolved for decades, has been cleared for release in weeks after implementing an RBR.

Using RBRs can be a powerful tool in treating liquid waste, providing an efficient and effective solution to a major industrial problem.

Possible Areas Where RBR Technology Can Be Used

- Water Treatment: Remediation of PFAS-contaminated water.

- Nuclear Waste Management: Effective treatment solutions for nuclear waste.

- Biochar Production: Utilizing RBR technology in biochar development.

- Drinking Water Remediation: Tackling serious pollutants like arsenic in drinking water.

- Textile Industry: Treating dye-polluted water and recycling process water.

- Waste Upcycling: Chemical, biochemical, mechanical, and thermal transformations of waste products.

- Pharmaceutical Industry: Scavenging and re-using transition metals, and recovering APIs and precursors.

Check out our application blog on how rotating bed reactors can revolutionize liquid waste treatment! Discover how this technology can handle very large volumes of liquids while reducing the mass and volume of waste by thousands of times.