Process development

Increasing the production efficiency, and reducing the material costs are generally the main goals, both when planning for the improvement of an already existing process, and when developing a brand new one. Process development involves the planning, testing, supervising and optimizing of the procedures, techniques and workflows of a certain process.

Trials and pilot plants

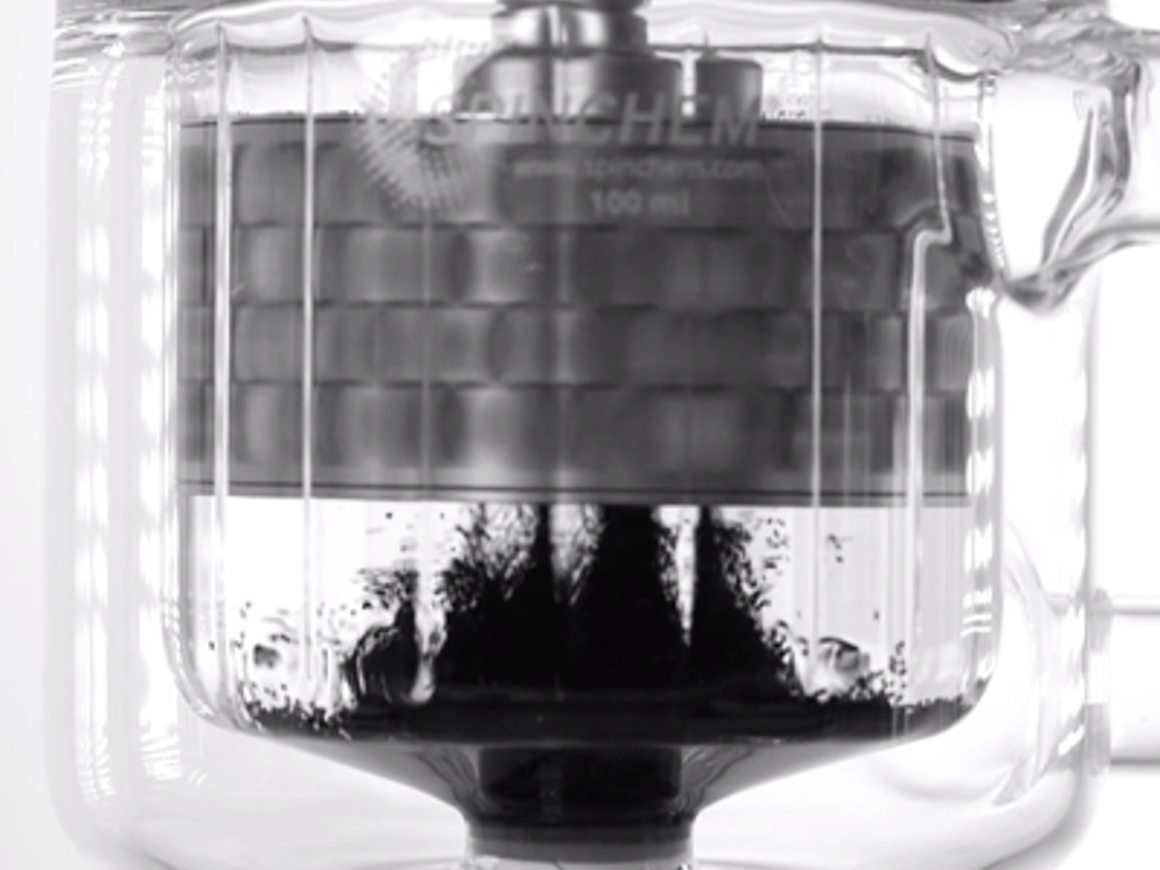

There are generally a few different steps in developing a new process. First off, laboratory trials are planned, tested and optimized to ensure satisfactory reaction conditions and product yields. This often includes testing of different materials, solvents, and reaction settings, to reach suitable results. The process is later moved over to a pilot plant for pre-commercial production runs, and further large-scale process optimization. This will offer a chance to study the set-up in a situation resembling the final process. In this step, parameters can be adjusted to ensure a maintained quality of the process at a larger scale. During these two initial phases it is also common to test out partially or complete automation of the process, as well as the incorporation of new tools and technological solutions. After the process has been tested and optimized for satisfactory results, it is ready to be moved on to production.

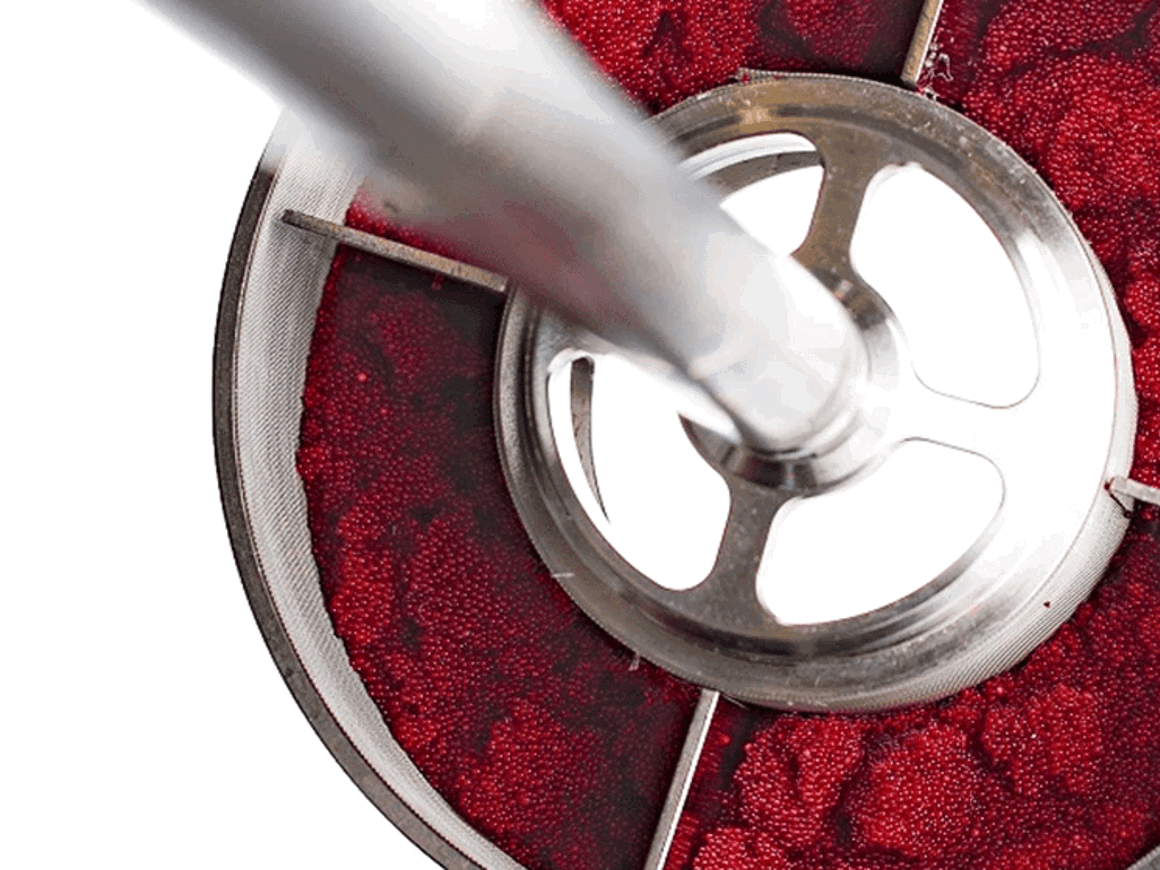

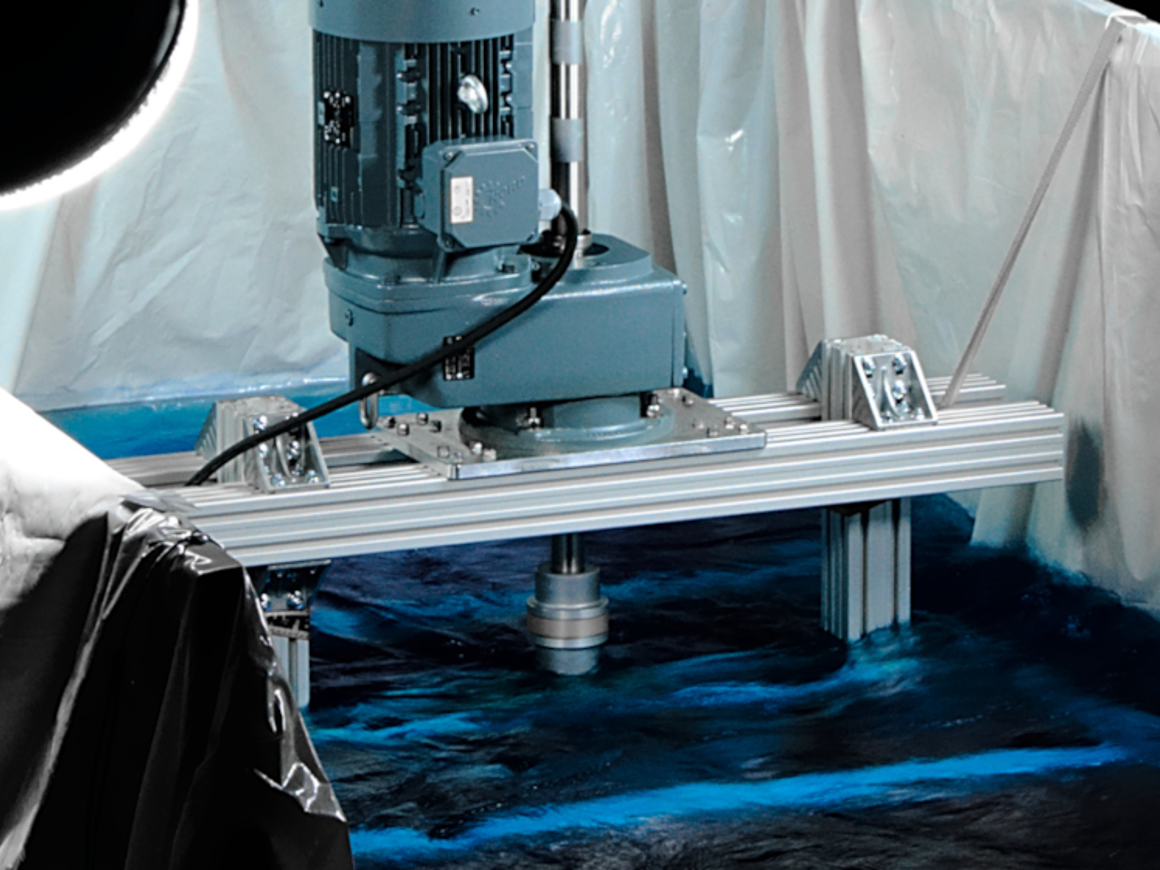

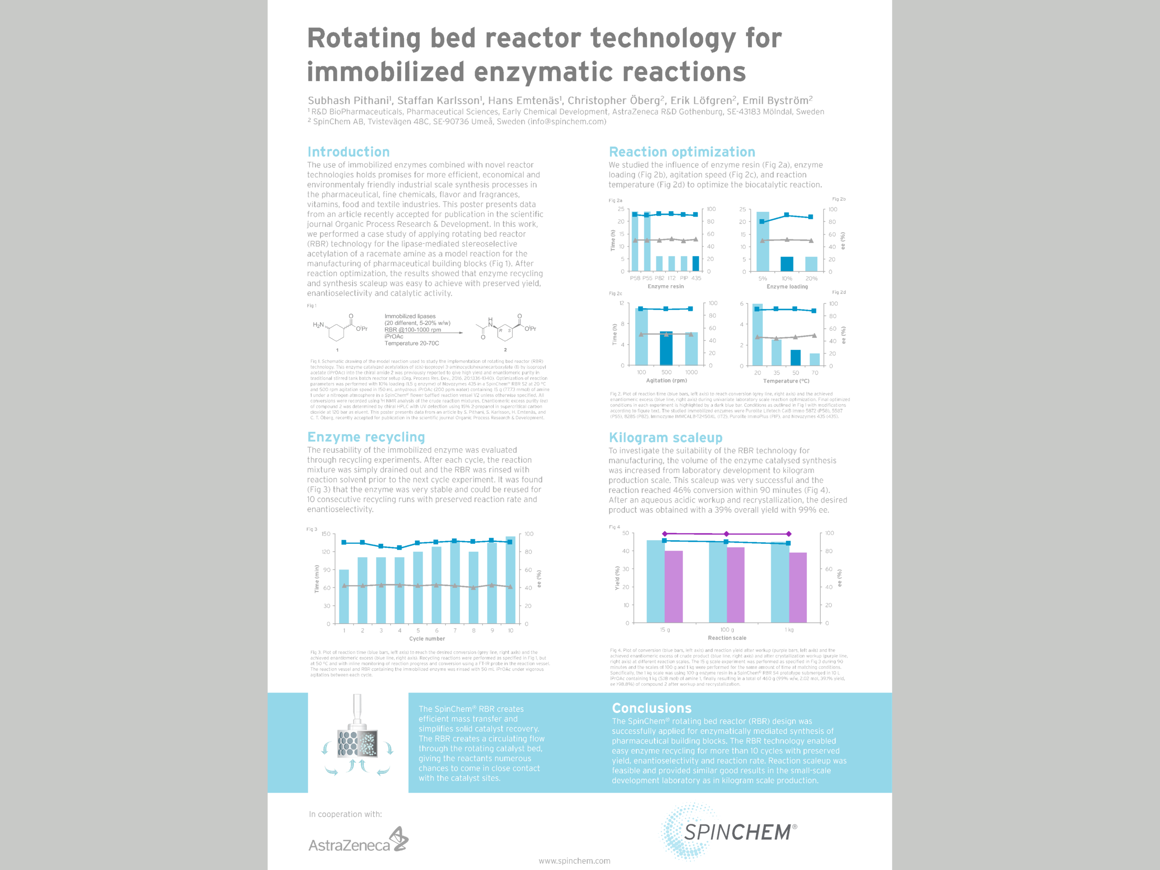

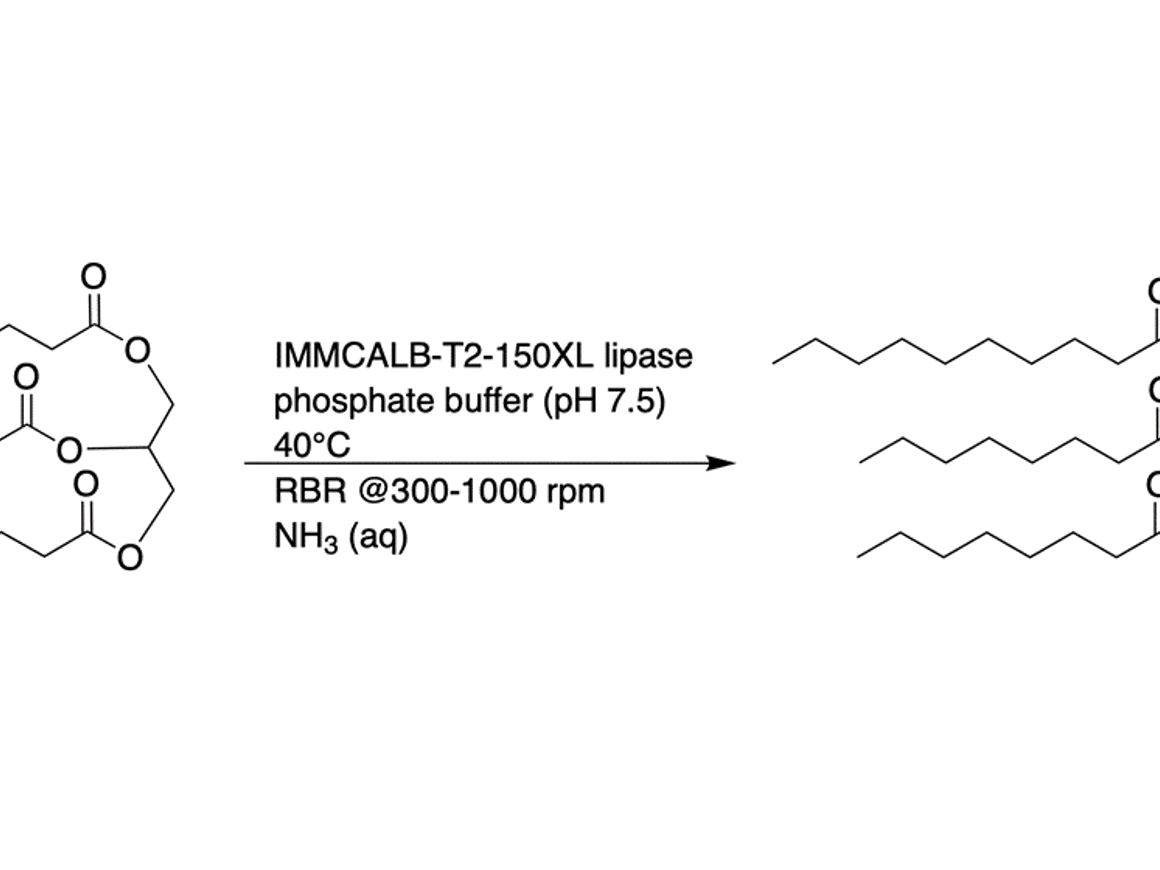

Rotating bed reactors

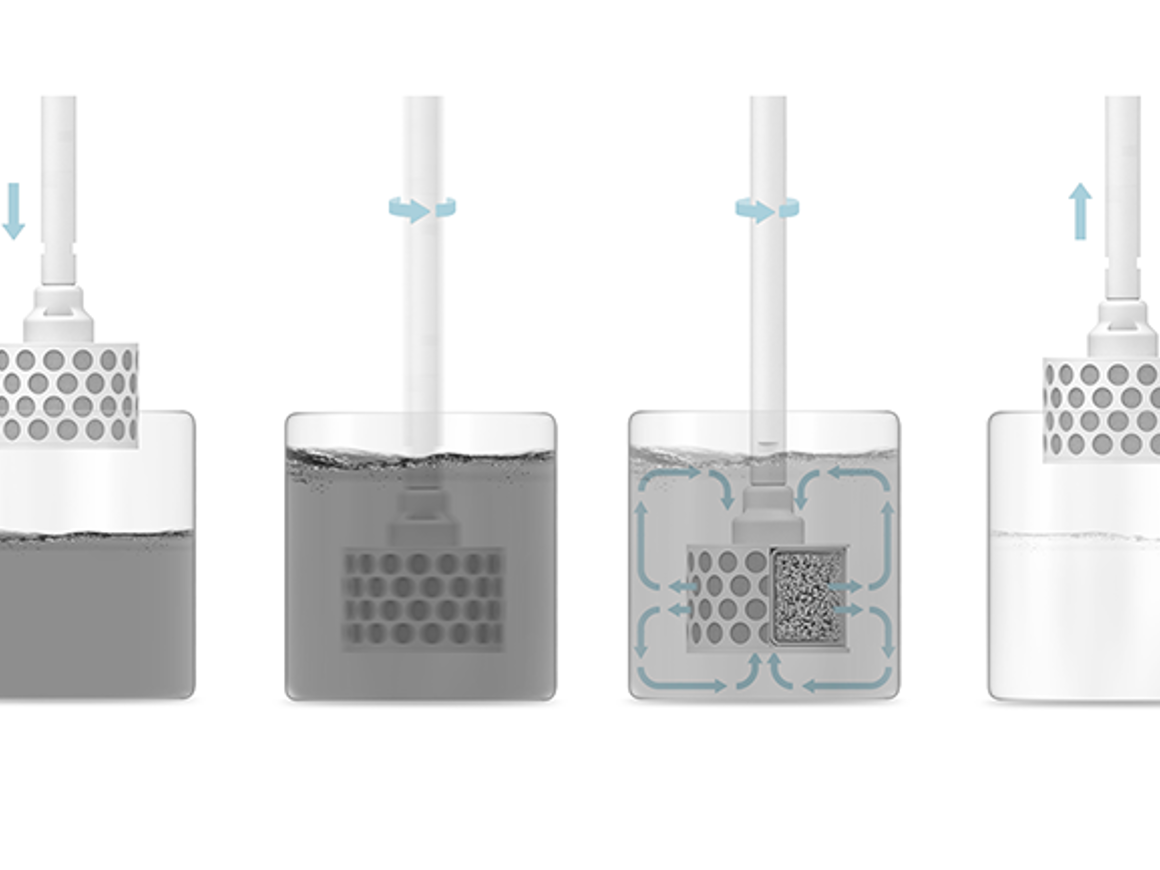

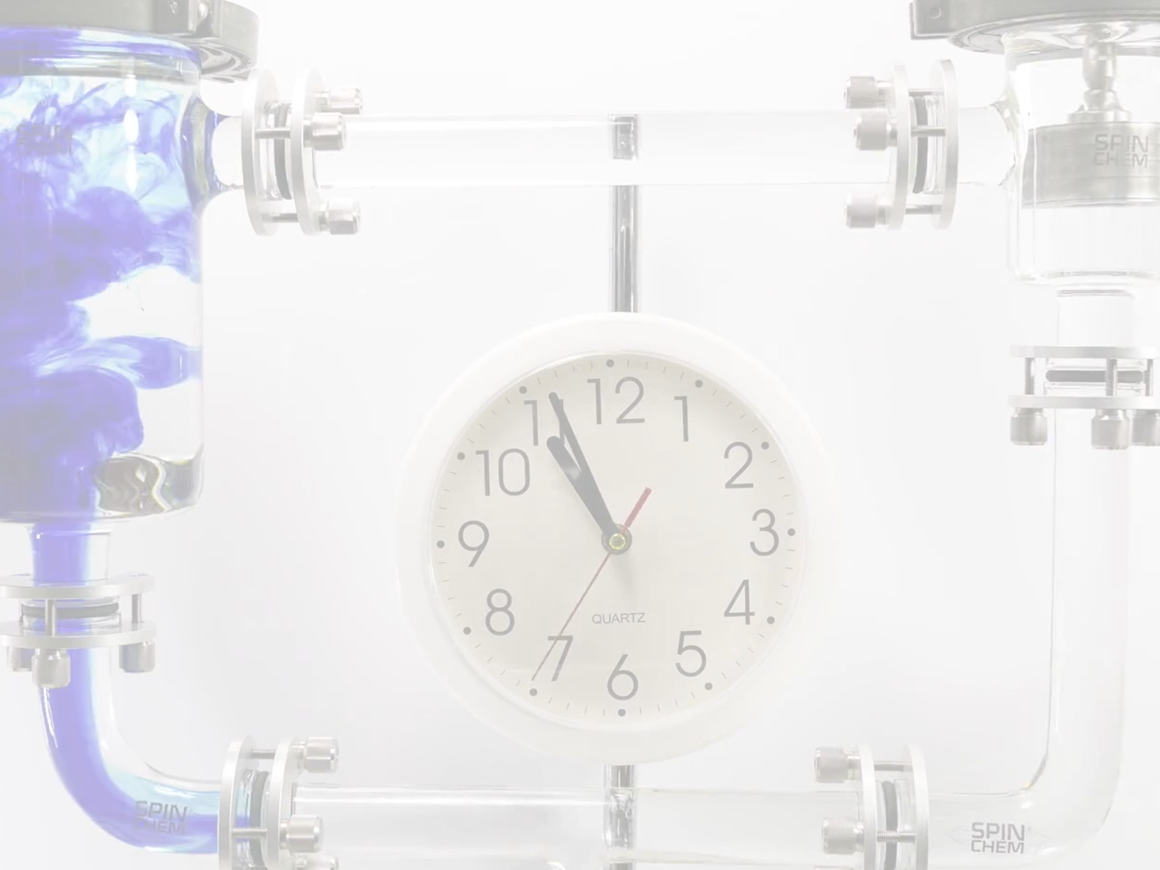

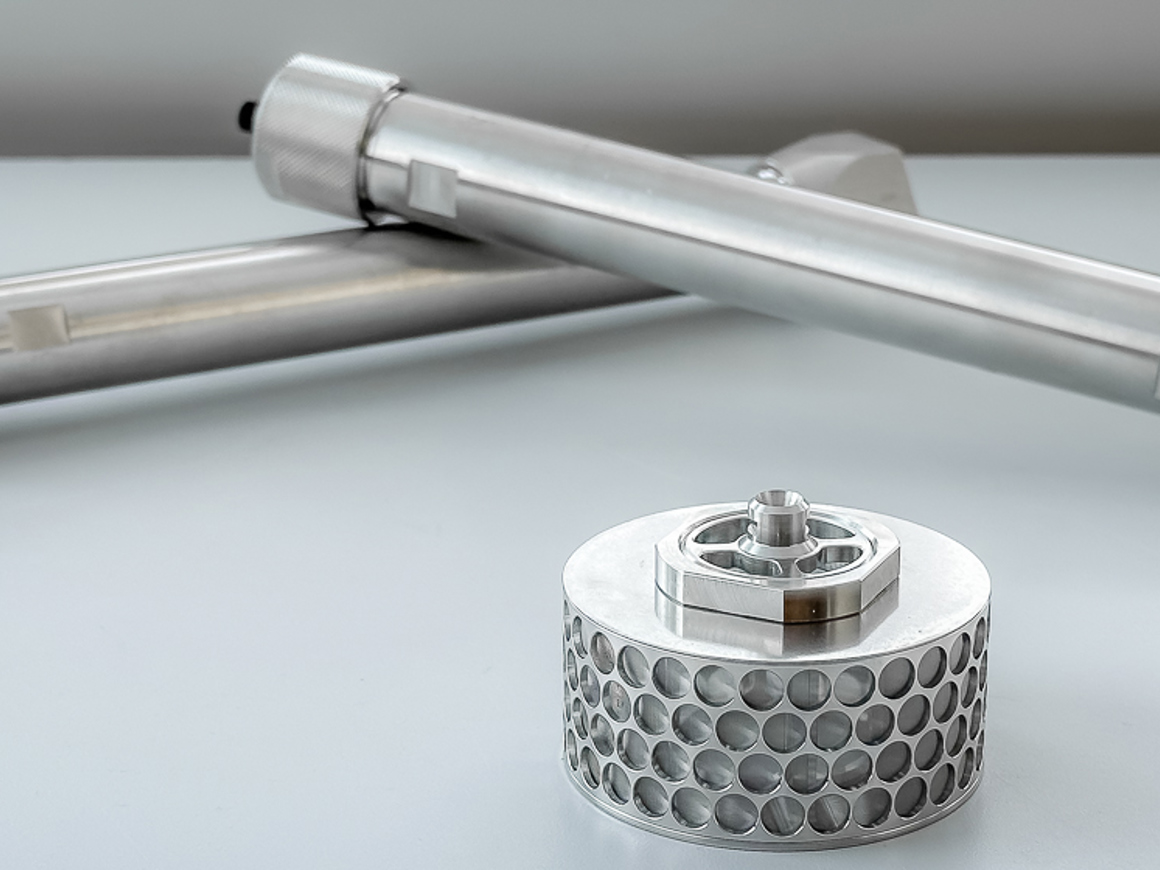

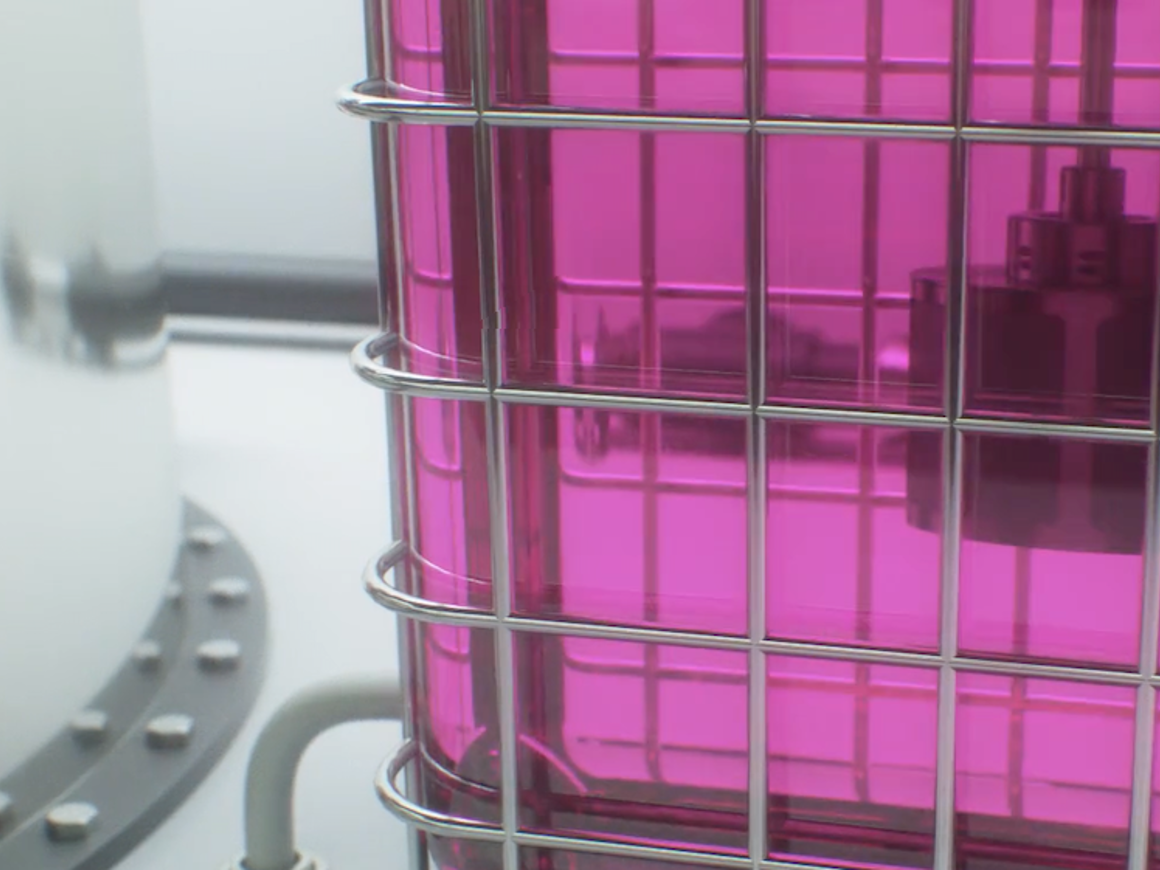

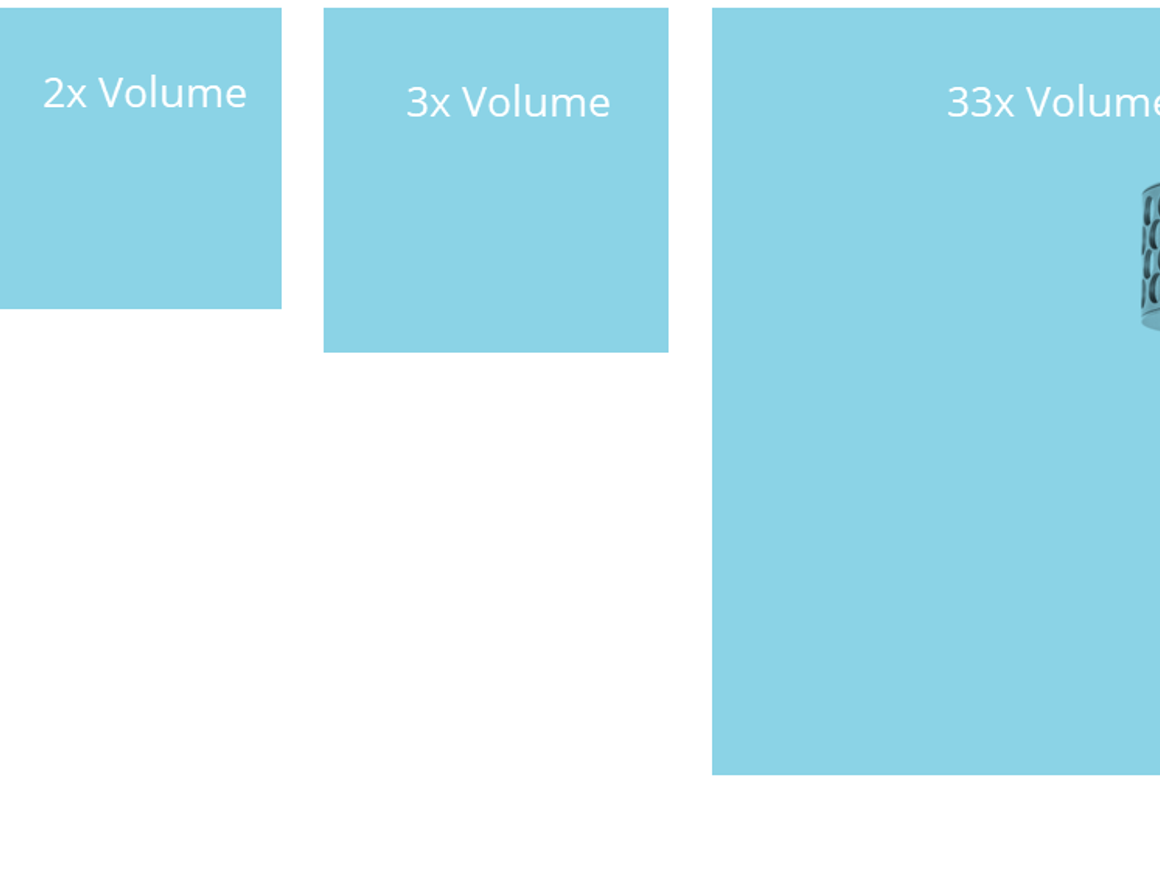

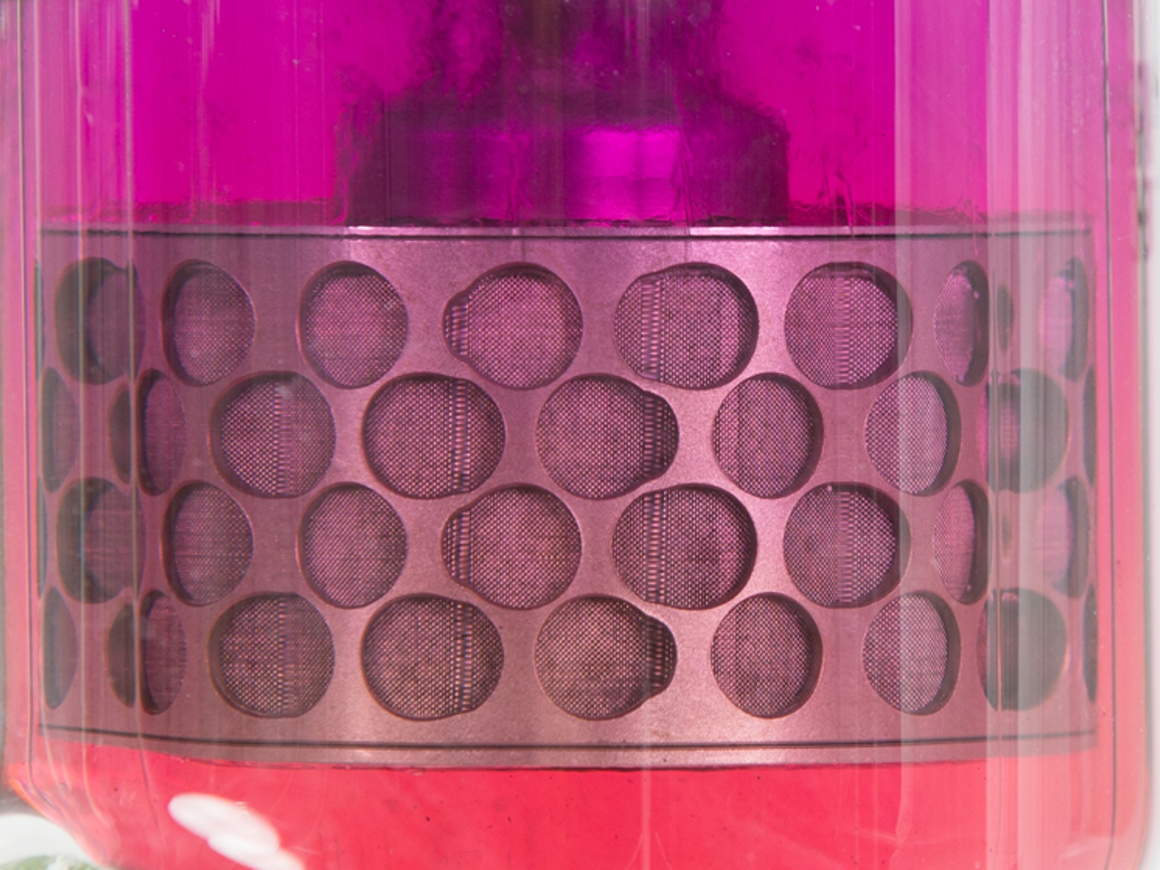

SpinChem offers help with the development of your heterogeneous processes, from bench-top screening, to full-scale production. Due to the generic design of the SpinChem® rotating bed reactor (RBR), the technology is fully scalable, and performs just as well in liquid phase volumes of a few millilitres (MagRBR), as in several thousand cubic metres of solution (ProRBR). If the existing set-up makes it impractical to use the RBR in-tank for batch processing, SpinChem offers other solutions, such as flow systems, where the RBR is used in a separate vessel connected to the main tank. The SpinChem® RBR can also be used in connected systems of reactor vessels, where the RBR is used in one or more of these vessels.

The efficient mass transfer achieved with the RBR, along with the fact that the solid phase is not exposed to mechanical forces or pressure, makes for quick and clean reactions. Downstream processing is cut to a minimum as there is no need for filtering of solid phase resin or debris from the reaction solution. This makes the SpinChem® RBR a very cost and resource efficient alternative both in research and production.

SpinChem’s fields of expertise include chemistry, engineering, experimental design, solid phase materials, and fluid flow simulations. Through rapid in-house prototyping, testing, simulating, analysis and optimization, SpinChem is able to develop clever, custom-made solutions to fit your processes and applications.