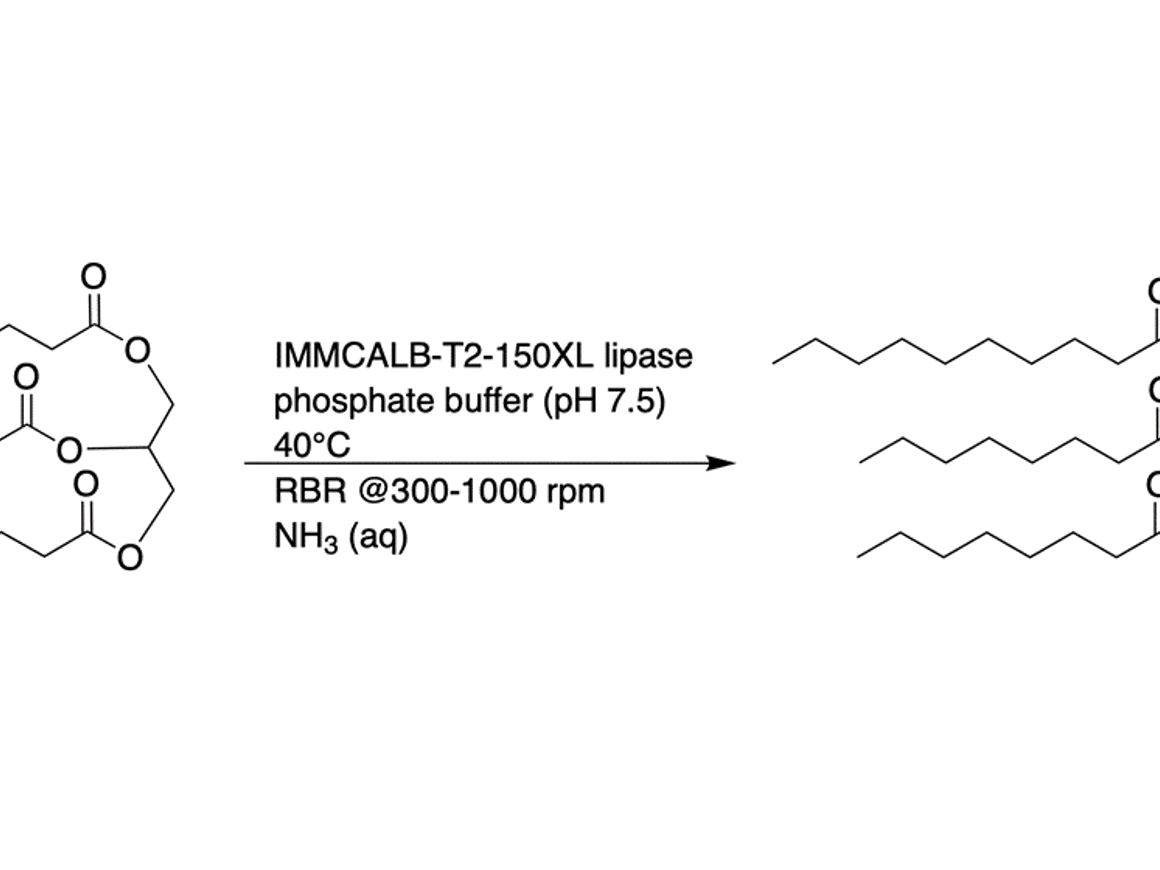

Intensified, Kilogram-Scaled, and Environment-Friendly: Chemoenzymatic Synthesis of Bio-Based Acylated Hydroxystyrenes

Philipp Petermeier, Pablo Domínguez de María, Emil Byström, Selin Kara ACS Sustainable Chem. Eng. 2024, 12(34), 12869−12878

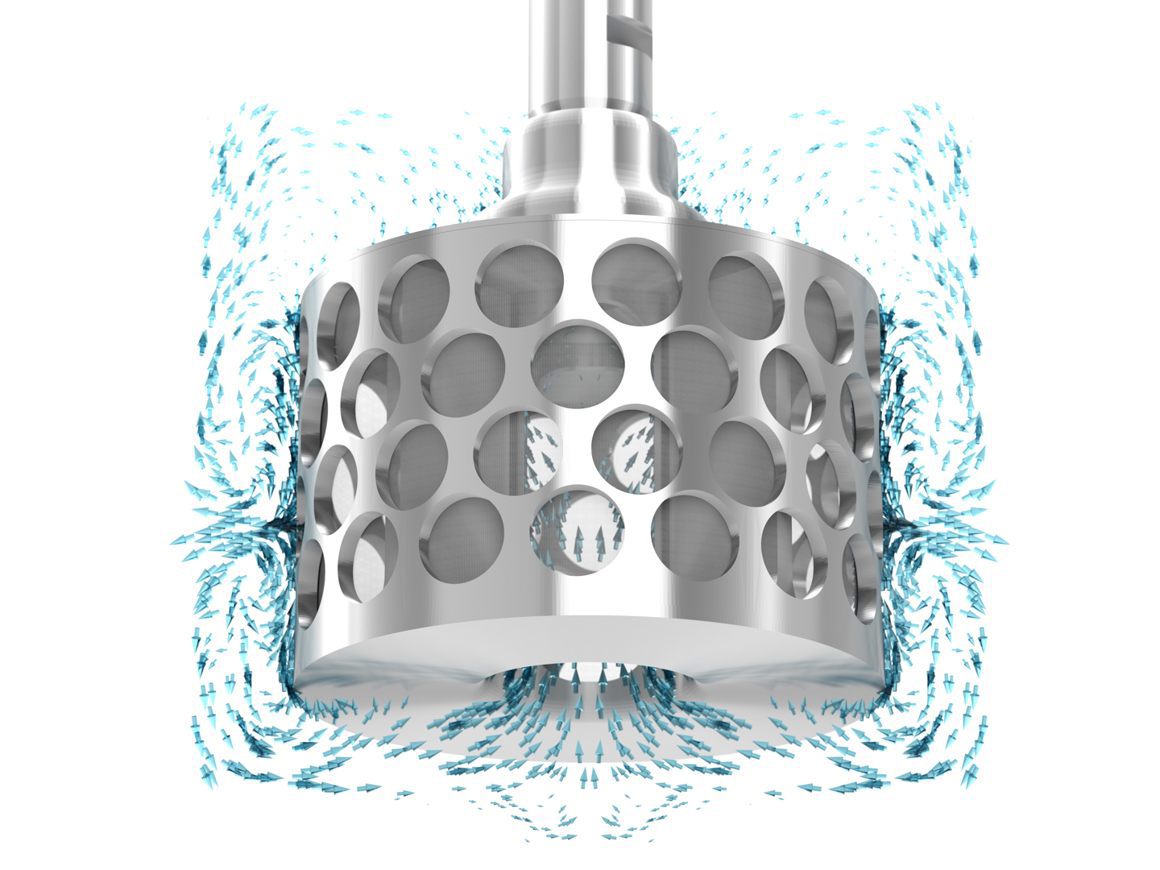

The SpinChem® Rotating Bed Reactor (RBR) is a patented technology designed to enhance chemical reactions and processes by optimizing mass transfer between the solid phase and the reaction solution.

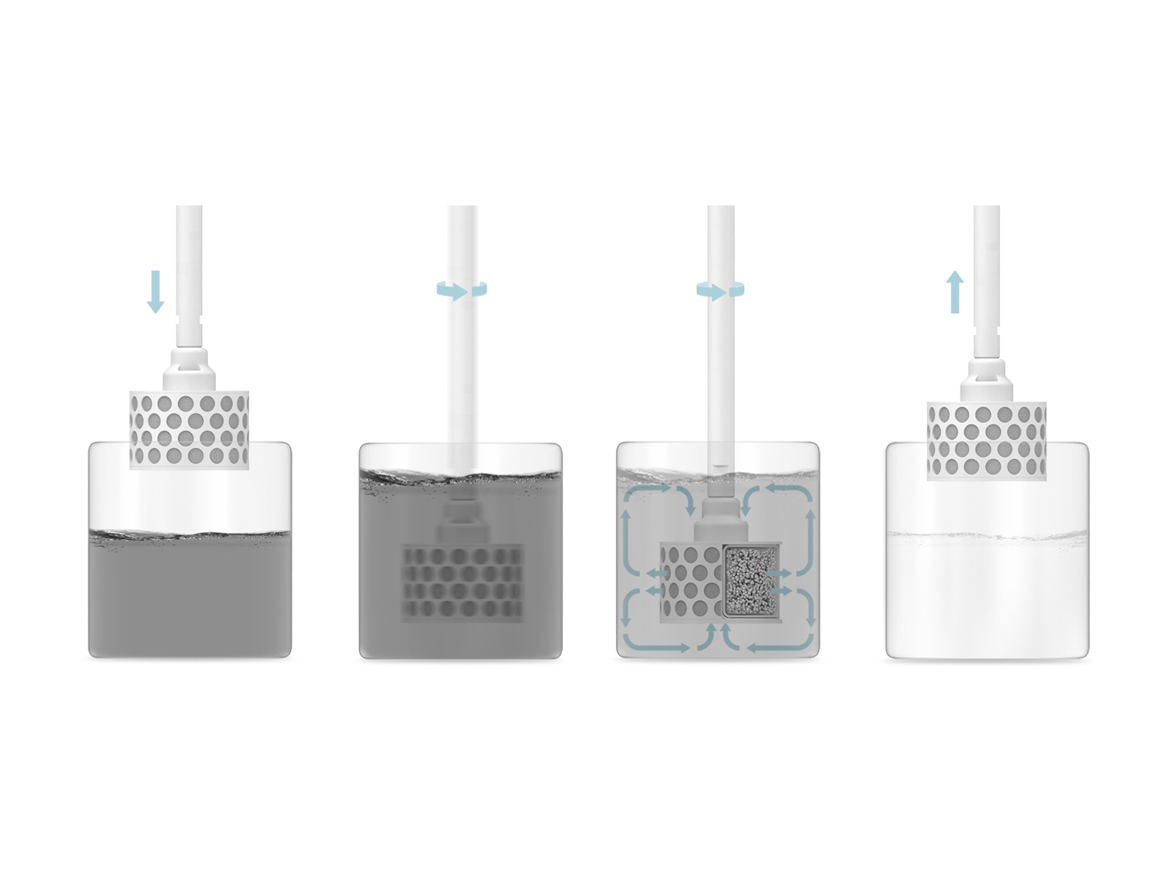

The SpinChem® Rotating Bed Reactor (RBR) eliminates slow reaction kinetics caused by poor mass transfer between your solution and solid phase. It works by holding the solid phase as a packed bed inside a rotating cylinder, creating a continuously circulating flow. This design rapidly aspirates the reaction solution from the vessel's bottom, percolates it through the solid phase, and quickly returns it to the vessel. The result is maximized axial mixing and convective transport.

This innovative design enhances mass transfer, reduces reaction time, and boosts yields. The RBR's efficiency extends to challenging scenarios, including reactions with immiscible liquids, liquids of different viscosities, and those requiring dissolved gases.

The SpinChem® Rotating Bed Reactor (RBR) features a flexible design that allows its use in various industries. Implementing the SpinChem® RBR typically leads to faster processes, higher yields, or reduced reagent consumption, depending on the specific application.

Moreover, the SpinChem® RBR minimizes grinding of catalysts extending their lifespan. It also simplifies the collection and recycling of the solid phase.

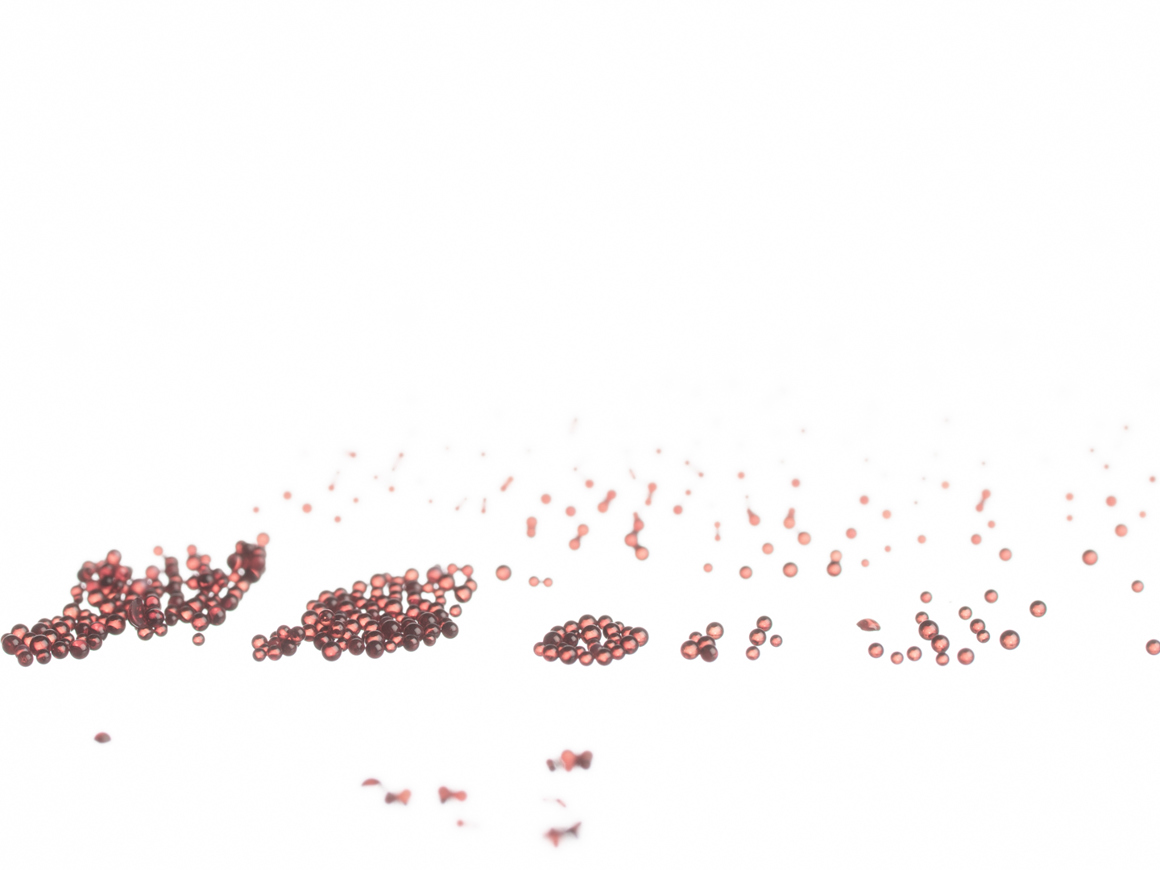

The SpinChem® RBR is versatile, accommodating various heterogeneous reactions with diverse solid phases. These include immobilized enzymes, encapsulated cells, and ion exchangers. It's also effective for purification processes using metal scavengers, activated carbon, and water adsorbents.

The RBR's flexible design allows for seamless integration into existing production lines and processes, causing minimal disruption. This adaptability caters to diverse sectors such as pharmaceuticals, water treatment, fine chemicals, and renewable energy production.

Thanks to its versatility, the RBR can address specific industry challenges—from meeting high-purity requirements in pharmaceuticals to efficiently removing pollutants in water treatment.

The SpinChem® RBR technology significantly enhances mass transfer rates compared to traditional fixed-bed or stirred tank reactors. This results in faster reaction times, higher yields, or reduced reagent consumption—depending on the specific process—and lower operational costs.

Additionally, due to the RBR's design, the lifetime of solid-phase particles is extended.

These benefits translate into more efficient processes, reduced cycle times, and decreased energy consumption, making the RBR an attractive investment for industries seeking to optimize their chemical processes.

The SpinChem® technology is fully scalable, enabling a seamless transition from laboratory to production scale. This adaptability makes it suitable for diverse industry sizes and needs, from small-scale experiments to full-scale industrial processes.

The scalability allows processing volumes ranging from 5 mL to 100,000 L with standard RBR models—and even larger volumes, up to thousands of cubic meters, with the ProRBR.

Philipp Petermeier, Pablo Domínguez de María, Emil Byström, Selin Kara ACS Sustainable Chem. Eng. 2024, 12(34), 12869−12878

Biocatalysis offers many benefits in the production of chemicals and active pharmaceutical ingredients. One major challenge has been the deployment of immobilized enzymes in an efficient way on large scale. The rotating bed reactor offers a convenient way to scale a biocatalytic process.

09 Dec 2021

With a SpinChem® Rotating Bed Reactor (RBR) you can eliminate slow reaction kinetics caused by poor mass transfer between your solution and solid phase.

Due to faster mass transfer

Due to protected solid phase

Due to the product design